In the intricate dance of global commerce, the importance of robust supply chain analytics has never been more profound. Supply chain professionals face an unprecedented era marked by converging global crises — inflation, a labor shortage the COVID-19 pandemic, and geopolitical tensions — all reshaping the business landscape. However, a guiding star is emerging amidst the chaos, and it’s something you can harness, explore, and optimize: Data.

By leveraging their existing data, companies can unlock hidden efficiencies, make informed decisions, and gain a significant edge over competitors. In this new environment, the shrewd use of data is not just an excellent option; it is necessary for your supply chain’s success and survival.

The Imperative of Data in Modern Supply Chain Management

Companies managing complex supply chains already possess a wealth of, often untapped, data that holds the keys to unlocking efficiencies, trimming costs, and boosting competitiveness. From inventory optimization to fine-tuning transportation expenditures, the value of data analytics in the modern supply chain is undeniable. With worldwide pressures from factors like inflation and conflicts such as the war in Ukraine, it’s now more imperative than ever to harness the insights provided by supply chain data.

The good news is that businesses likely have all the data they need to begin this optimization journey.

Recognizing Underutilized Data

Companies are awash in data. However, much of this information goes underutilized or entirely ignored. Examples of underused data may include:

- Vendor Performance Data: Assessing vendor reliability and performance is crucial. Ignoring this data can lead to poor decision-making in vendor selection and management.

- Second-Tier Supplier Data: A McKinsey & Co. report found that only 2% of companies leverage visibility beyond second-tier suppliers. This lack of insight into the materials provided to first-tier suppliers can hinder the ability to assess risk and sustainability factors.

- Real-Time Inventory Management: Not collecting real-time data on inventory level results in excess stock or stockouts, impacting customer satisfaction and financial performance. Real-time inventory cannot be captured using a traditional method, like spreadsheet planning.

- Customer Feedback and Behavior: Understanding customer needs, preferences, and behavior patterns is essential to forecasting customer demand but can be overlooked in traditional supply chain data analysis.

- Global Market Trends: Awareness of macroeconomic factors like inflation, geopolitical events, and industry trends is essential for strategic planning, yet this broader context is often missing from supply chain decision-making.

Challenges and Solutions: Disparate Datasets and Technology

Another challenge businesses often face is the dispersal of their manufacturer, distributor, freight/ logistics vendor, and IoT sensor data across various systems. This makes data management and analysis complex and unwieldy. Siloed data gives a limited view of information, leading to delays and inefficiencies in decision-making processes. Without a centralized source, such as a supply chain optimization solution like GAINS, putting together a complete picture of your supply chain operations can be frustrating and time-consuming, hindering the responsiveness and agility needed in today’s environment.

Centralizing data, leveraging advanced analytics, and investing in cloud-based solutions can significantly improve efficiency, accuracy, and agility. Disparate datasets present a significant challenge for businesses, especially in the complex field of supply chain management. However, these challenges can be overcome with proper guidance and planning.

Common Data-Related Supply Chain Challenges

1. Inefficiency in Decision Making: Siloed data prevents a comprehensive view of information, leading to delays and inefficiencies in decision-making processes. Pulling together a complete picture without a centralized source can be time-consuming, hindering critical responsiveness in a rapidly changing environment.

2. Lack of Coordination: Disparate datasets lead to a lack of alignment across different supply chain segments. This misalignment can cause conflicts in planning and execution, resulting in duplication of efforts and missed opportunities.

3. Increased Costs: Managing multiple siloed datasets often requires more resources and can be more expensive, sometimes requiring separate tools, additional expertise, and infrastructure to maintain and analyze, driving up operations management costs.

4. Inaccurate Analysis: Analyzing data in silos can lead to inconsistencies and inaccuracies.Using standardized tools and practices for data analysis ensures uniformity and accuracy.

Combining Talent and Technology for Success

For a supply chain leader, harnessing this overlooked data requires a combination of the right talent, data scientists, and technology, like AI and machine learning. Even the most valuable data may remain hidden and unused without these tools. By partnering with the GAINS team, you can unlock your potential without diverting focus from your core responsibilities. Specialized expertise, advanced tools, and a tailored approach ensure that you identify and analyze overlooked data and transform it into a strategic asset that fuels growth, innovation, and competitive advantage.

The journey to supply chain excellence need not be solitary; with the GAINS team, you’re well-equipped to navigate the challenges and seize the opportunities that lie ahead.

- Cost-Effective Solutions: While building an in-house team and investing in advanced technology may seem daunting, partnering with the GAINS team provides access to top-tier talent and tools without the heavy upfront investment. Their flexible engagement models can be tailored to suit your budget and needs, providing value for money and maximizing ROI.

- Assessment and Identification: The GAINS team can comprehensively review your existing supply chain management process and data streams, pinpointing areas where valuable data may be underutilized or ignored. GAINS can identify and align the key performance indicators relevant to your business goals with available data sources.

- Advanced Analytics and Insights: Using cutting-edge technologies like AI and machine learning, the GAINS team delves into the data to uncover hidden patterns, trends, and insights. Whether it’s predictive analytics for demand forecasting or optimization algorithms for inventory management, their expertise can transform raw data into actionable intelligence. According to Nucleus Research Nucleus noted that when organizations leveraged GAINS for forecasting, planning, and reporting, they decreased reporting times by an average of 65-80 percent.

- Strategic Guidance and Planning: Beyond analysis, the GAINS team can help you translate data-driven insights into strategic initiatives and actionable plans. Their deep understanding of supply chain dynamics ensures that recommendations are grounded in industry best practices and tailored to your unique business context.

- Ongoing Support and Monitoring: Implementing changes based on data insights is just the beginning. The GAINS team can provide ongoing support, monitor the effectiveness of your solutions, and make necessary adjustments. Continuous improvement is at the heart of their approach, ensuring your now efficient supply chain remains agile and responsive to ever-changing market conditions.

Features of GAINS Solution to Address Supply Chain Data Challenges

- Data Integration Tools: Tools like GAINS allow businesses to pull together data from various sources into a centralized location, enabling a cohesive and comprehensive view.

- AI and Machine Learning: Data is the foundation for artificial intelligence and machine learning and GAINS advanced analytics powered by AI, machine learning, and best practices provide insights beyond traditional methods, offering predictive and prescriptive analytics vital for optimizing your supply chain.

- Cloud-Based Platforms: GAINS uses a cloud-native design to host its solution in a unified, accessible environment, facilitating collaboration scalability and reducing the need for IT resources for maintenance and repair.

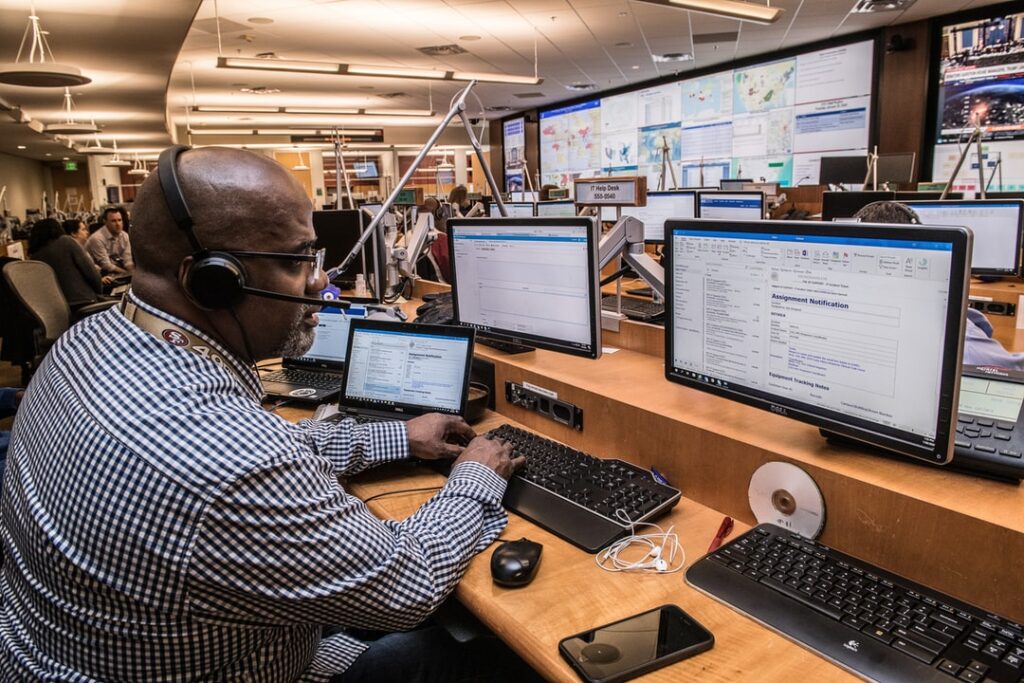

- Digital Dashboards: GAINS provides real-time dashboards that pull data from various sources, giving executives and team members immediate access to vital information improving collaboration and decision-making.

Supply Chain Performance as a Key Differentiator

Success in the data-driven supply management world requires a combination of skilled talent and cutting-edge technology. Building from the ground up on your own can be difficult and costly. However, investing in supply chain partners offering digital dashboards, cloud-based platforms, and artificial intelligence aids in unifying discordant datasets in visually comprehensible ways.

As the world spins into an increasingly complex and challenging era, the data-driven approach is a beacon for supply chain professionals looking to “GAIN” a competitive edge. The roadmap is clear: understand, centralize, and optimize the treasure trove of data that businesses already possess.

With careful planning, investment in technology and talent, and a firm grasp on the ever-shifting global landscape, supply chain professionals can leverage data to redefine success and resilience in these trying times. The winners of tomorrow will be those who embrace this paradigm today, ensuring a competitive edge in the intricate and evolving dance of global commerce.

To learn more about how GAINS can optimize your supply chain planning, effective supply chain management, and improve your customer service levels, click the button below to request a demo.

Request a DemoOther Reading

The Key Features of an Optimized Demand Plan

Signs It’s Time To Re-evaluate Your Demand Planning Tools

Why Cloud-Native Supply Chain Solutions are the Best Bet for Supply Chain Planning