Manufacturing

Decision intelligence that drives outcomes for manufacturers.

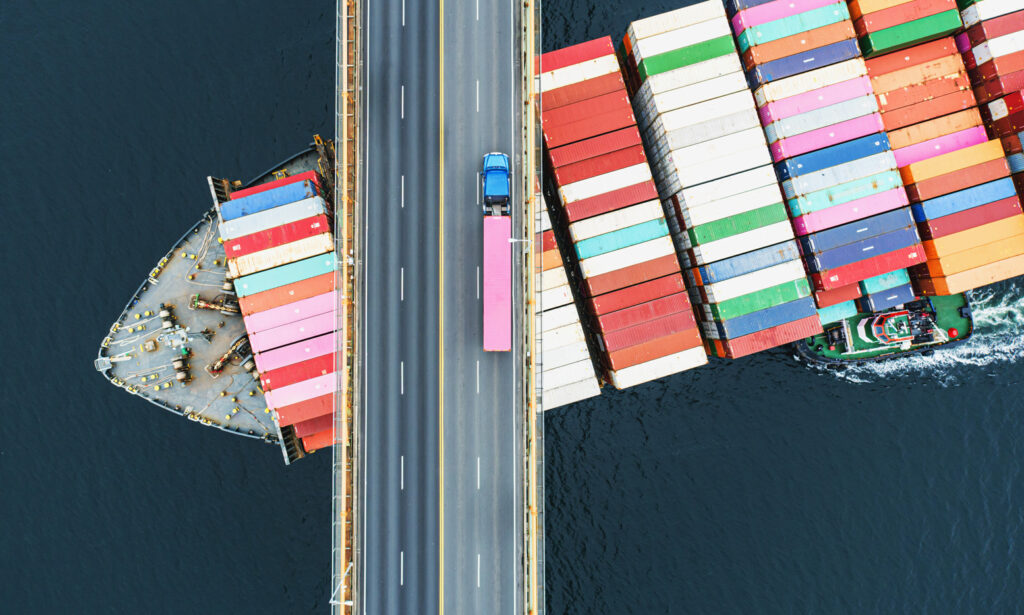

Whether your company manufactures consumer goods, industrial supplies or automotive/aerospace parts, GAINS provides the visibility and decision intelligence you need to get the right products to the right places at a lower cost. The GAINS supply chain optimization platform is used by a long list of industry-leading manufacturers to drive competitive advantage.

Discover the difference GAINS makes for manufacturing leaders.

Enhance Visibility

If inventory matters in your business, supply chain costs no doubt significantly impact your company’s profitability. By providing a clear line of sight into the supply chain planning process, GAINS gives CFOs visibility to supply chain cost savings achieved with GAINS including streamlining inventory management, reducing transportation expenses, and minimizing stockouts or excess inventory.

Free Up Working Capital

CFOs need to ensure that the company has sufficient cash flow to meet its operational needs. By aligning supply chain planning with financial forecasting, GAINS makes it easier to predict cash flow requirements and effectively manage working capital, controlling your inventory investments across your network.

Reduce Risk

GAINS provides the insights CFOs need to assess and manage risks associated with volatile supply chain, such as supplier disruptions, geopolitical events, natural disasters, or regulatory changes. By integrating risk management strategies into supply chain design and planning, the GAINS platform empowers CFOs to mitigate potential financial risks from disruptions and ensure business continuity.

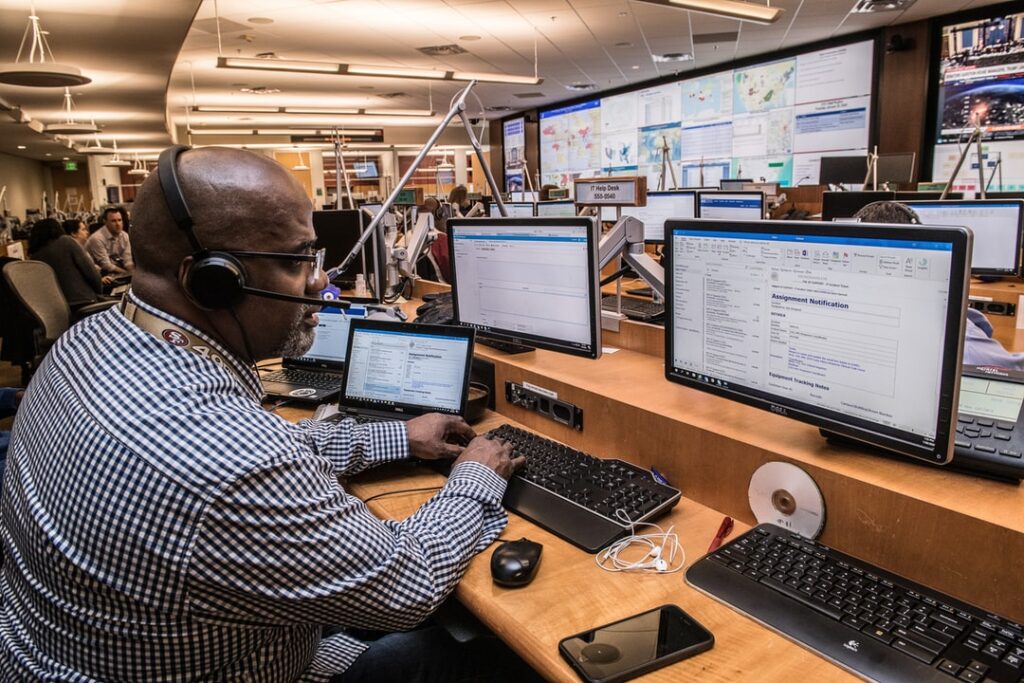

GAINS informs or automates millions of supply chain decisions a day.

Key Capabilities

Dynamic monitoring

Continuously analyze demand and supply in near-real-time to revise inventory policies and/or replenishment plans.

Optimized demand planning and forecasting

Multi-echelon planning optimization driven by total (independent and dependent) demand, demand sensing & signaling, outlier detection, and more.

Make-to-stock / Make-to-order optimization

Determine profit-optimal trade-offs between various inventory policy scenarios.

Synchronized optimization

Production policies, schedules, and set-ups are profit-optimally synchronized to customer orders

Compatible with any ERP

Whether your organization has one or multiple ERP systems, or even homegrown spreadsheets, integration with GAINS is data-agnostic, and is SAP and Oracle Certified.

Explore other solutions

We saved $14 million in six months. We are often promised these kinds of numbers; we’re just not used to having them delivered, GAINSystems, beyond a doubt, delivered.

Wing Commander

The GAINS project provided the greatest corporate ROI in the history of the company.

John Walker, President and CEO of QubicaAMF