Supply chain planning is essential for every successful business, from multinational corporations to regional distributors. Planning is not a new concept; it has been around since the introduction of mass production. In one form or another, the humble Excel spreadsheet is more widely used in supply chain planning than any other tool. They remain powerful tools for business users, but like any system, they have their time and place.

The History of Spreadsheets

The first digital spreadsheet program was VisiCalc, written for the Apple II computer in 1979. Its capabilities showcased the possibilities for small businesses to easily manage large quantities of data at a relatively low cost.

There have been many technological advances, including the creation of the World Wide Web, the invention of the cellphone, and the coming and the going of the DVD. But one thing has stood the test of time, the spreadsheet, and for a good reason, everyone can use them, and the price is right. However, even if a product is free, it does not mean it won’t cost you, as JP Morgan Chase learned in 2013 when the bank lost almost $6 billion due to a mistake in a spreadsheet cell.

This article will discuss the advantages and disadvantages of using spreadsheets for supply chain planning. Let’s start with the Pros.

Pros of using spreadsheets for supply chain planning:

Overall, spreadsheets are adaptable tools that can be used for various purposes in everyday life, and most people are familiar with them, so training costs are low. The advantage of using spreadsheets is their versatility. Excel can track and manage personal finances, build to-do lists, and budget for vacations, including tracking expenses, itinerary planning, and booking details. Spreadsheets are:

- Cost-effective: Spreadsheets are relatively inexpensive and come standard with the Microsoft Office suite or are available for free online through Google Sheets.

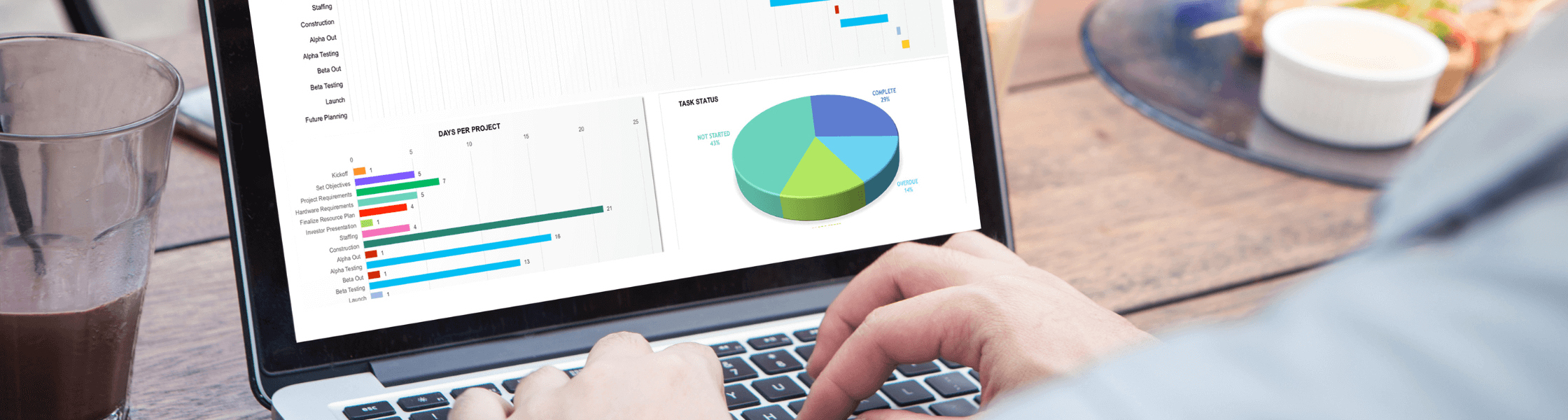

- Flexibility: Spreadsheets offer great flexibility regarding data input and manipulation. You can customize formulas and macros according to your needs, allowing you to analyze and visualize data differently. This advanced use takes some expertise and a lot of manual effort. Online resources, including AI like ChatGPT, can write spreadsheet formulas and help you with various formulas and functions to inform decisions.

- Accessibility: Spreadsheets are widely used and can be easily shared with others, making collaboration easier. However, some spreadsheets have limited functionality regarding collaboration and governance, making it challenging to work on a spreadsheet with multiple people. For example, some spreadsheets may not allow multiple people to simultaneously work on the same sheet. This overlapping work can lead to confusion and mistakes, including data conflicts and errors if people work off of different versions of the same document. Also, when multiple people are working on a spreadsheet, tracking the most up-to-date version can be challenging.

While on the surface, using a low-cost, easy-to-understand tool that lets you freely manipulate data seems like a clear choice for supply chain planning; if it looks too good to be true, it probably is.

Let’s look at the downside or cons of using spreadsheets like Excel or Google Sheets for supply chain planning.

Cons of using spreadsheets for supply chain planning:

- Limited scalability: For small businesses without many SKUs to consider, spreadsheets may seem like an ideal choice, as they are low-cost and easy to use. However, spreadsheets can become cumbersome and slow when dealing with large datasets or complex calculations that a modern supply chain requires. Spreadsheets can effectively analyze large amounts of data to a certain extent, but there are limits to what they can handle. It may be better to use specialized data analysis software for extensive datasets. When the quantity of data exceeds the capacity of the spreadsheet, it can lead to data loss or other issues. In short, a spreadsheet may not be the most efficient tool as your business and supply chain grows.

- Error-prone: While spreadsheets are accurate when used correctly, mistakes can quickly occur due to human error, such as copying and pasting data incorrectly or using incorrect formulas. The European Spreadsheet Risks Interest Group states that “more than 90% of spreadsheets contain errors. Because spreadsheets are rarely tested, many errors go undiscovered. As a result, frequent users of spreadsheets are overconfident. Because they rarely look at underlying formulas for mistakes, they rarely find any. They assume their spreadsheets are correct and working, as they find none.

Meanwhile, the truth is that some 50% of spreadsheets used operationally by businesses have material defects.” If you are using spreadsheets for planning, when there are errors, it can take a lot of effort to locate and fix the problem. This correction process can involve reviewing large amounts of data, debugging formulas and functions, and testing different scenarios to identify the source of the error.

- Time-consuming: Creating and maintaining a spreadsheet can be time-consuming, especially if you have a lot of data to manage. Data entry can be a time-consuming task depending on the complexity of the supply chain data. It may require manual efforts to key in data or import data from external sources, which can be time-consuming and prone to errors, all of which open you to unnecessary risk. Additionally, formatting a spreadsheet takes time and expertise beyond a standard user’s. Especially if a large amount of data or create complex formulas are required. This data manipulation can include changing report layouts, applying conditional formatting, and creating custom styles. You’ll spend more time on data entry and analysis than with dedicated supply chain planning software like GAINS.

- Lack of integration: Spreadsheets are standalone tools that do not integrate well with other software systems. If you are using different data management tools, it may be challenging to integrate them with an Excel spreadsheet.

Despite the apparent limitations, spreadsheets remain a popular tool for supply chain planning for several reasons, such as being cost-effective, flexible, and accessible. While spreadsheets are adaptable and widely used, it is essential to consider their limitations when deciding whether to use them for supply chain planning. Spreadsheets may not be the most efficient tool to use as your business grows due to their limited scalability, being prone to errors, and the amount of manual effort they require. Also, spreadsheets lack integration with other software systems, making working with your other supply chain management tools difficult.

Using an integrated supply chain planning solution offers several advantages over using spreadsheets or other standalone tools, including:

- Increased efficiency: GAINS can automate many of the manual processes involved in supply chain planning, freeing up time for more strategic tasks and increasing efficiency and productivity while reducing the risk of human error.

- Better data decisioning: GAINS uses various supply chain data and analytic models for better decision-making and more accurate forecasting. Its solutions deliver rapid results by right-sizing inventory levels, improving order accuracy, and increasing customer satisfaction.

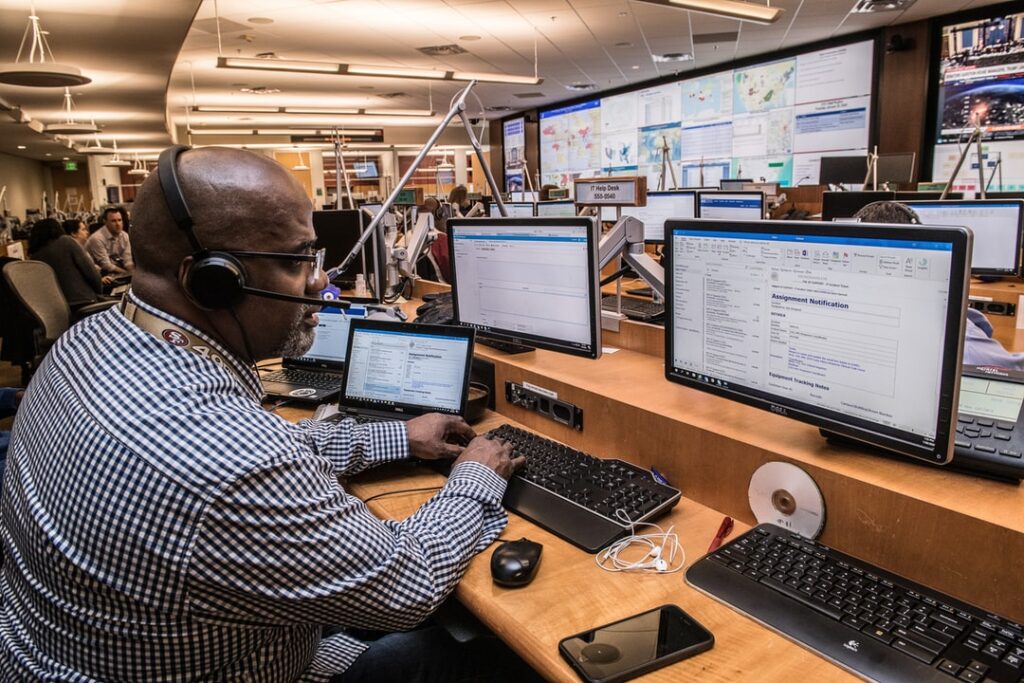

- Improved collaboration: GAINS empowers better collaboration across different departments and stakeholders, enabling better communication and alignment. This visibility can help reduce lead times and improve the overall responsiveness of the supply chain.

- Scalability: GAINS can handle larger datasets, including exogenous data, and more complex calculations than spreadsheets, making it a better choice for larger organizations or those with more complex supply chain networks.

- Integration with other systems: GAINS can be integrated with other systems, such as ERP or warehouse management systems (WMS), providing a complete view of the supply chain and helping to streamline operations.

In conclusion

Integrating an advanced supply chain planning solution like GAINS will help your business to manage its operations better, improve efficiency and accuracy in your data, and increase customer satisfaction. It can also help boost employee satisfaction, leading to your planners spending less time finding and fixing mistakes and more time doing jobs that require other, more valuable skills. We hope you found this look at spreadsheets helpful.

We’d love to learn more about your supply chain planning experience and how we can help you better manage your unique supply chain issues. Contact us to speak to one of our GAINS supply chain experts.