Agility, Efficiency, Profitability: The Triple Crown of Supply Chain Design

The Very Abridged History of Supply Chain Design

Pre-Industrial Era – Post WWII

Before the Industrial Revolution, supply chains were relatively simple and local. There was little concept of “design” as the supply chain network design was primarily a function of immediate necessity and availability.

In the post-World War II era, with the rise of multinational corporations and global trade, supply chains became more complex and geographically dispersed. Companies started to recognize the importance of logistics and planning as key elements of their business models. In the 1970s and 1980s, companies like GAINS began using software for inventory control, demand forecasting, and logistics planning. GAINS developed its early optimization models for supply chain design around this time.

1990s to Present

The 1990s saw the introduction of ERP Systems Enterprise Resource Planning or ERP systems, offering an integrated approach to business processes and supply chain management. Companies then had a more unified view of their operations, aiding in better efficiency. The rapid growth of e-commerce and the internet boom of the early 2000s necessitated agile and responsive supply chain designs to meet consumer demand for fast and reliable delivery. The 2010s witnessed the integration of advanced analytics, Big Data, and Artificial Intelligence into supply chain design. These technologies allowed for real-time tracking, predictive analytics, and more sophisticated optimization models.

The evolution of supply chain design from its pre-industrial roots to its modern incarnation has been marked by increasing complexity and sophistication, primarily enabled by technological advancements. Having traced this historical arc, it becomes clear why today’s supply chains require a meticulous and strategic approach to design. Each core element, from network configuration to risk management, is shaped by decades of advancements.

Let’s delve into these core components that define the modern supply chain and consider how they interact to create a resilient, efficient system.”

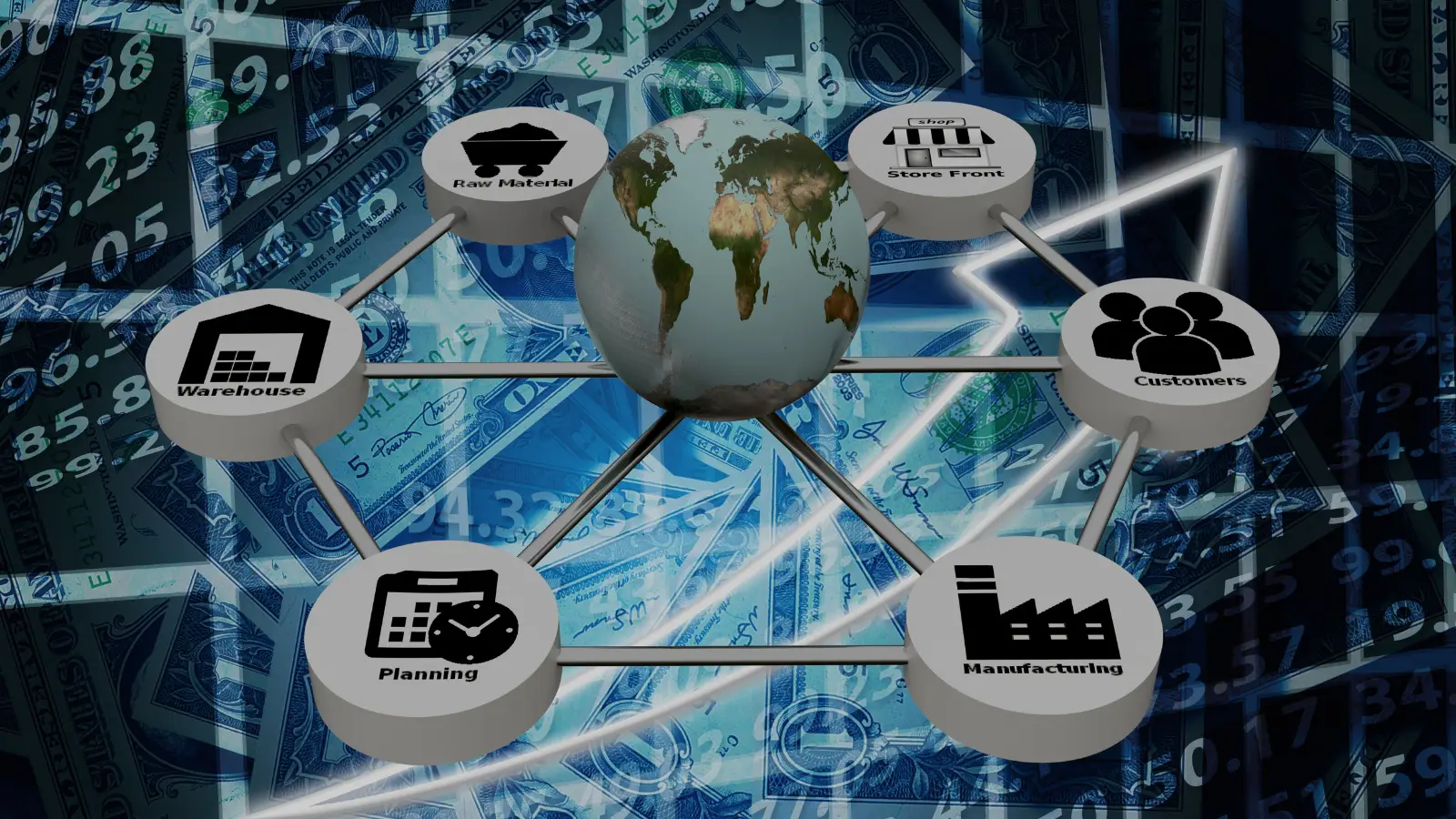

Core Elements of Supply Chain Design

Network Configuration: The foundational structure of a supply chain involves strategic planning around the locations and capabilities of suppliers, manufacturing sites, distribution centers, and retail outlets. Take an automotive manufacturer as an example: the company may position its manufacturing sites closer to critical markets and nearby distribution centers optimized for those regions.

Sourcing and Procurement: The next step is identifying and establishing relationships with key suppliers for essential materials and products. For instance, an electronics retailer might partner with market leaders in various categories.

Inventory Management: Effective inventory management specifies the inventory type, quantity, and location. An online fashion retailer, for example, could centralize most inventory but maintain smaller hubs near large customer bases for faster deliveries.

Transportation and Logistics: This involves the planning and execution of goods transportation from suppliers to manufacturing facilities and then to distribution centers and end consumers.

Forecasting and Demand Planning: Accurately predicting customer demand is crucial for aligning supply chain operations, reducing costs, and elevating service levels.

Risk Management: Identifying and mitigating potential risks, such as supplier failures or geopolitical instabilities, is imperative to ensure the supply chain’s resilience and performance. (Read GAINS VP of Solution Strategy Jeff Metersky’s thoughts on Mastering Risk Mitigation here.)

While the above is in no way an exhaustive list, each of these elements can substantially impact the performance and resilience of a company’s supply chain. Hence, a holistic approach is essential for effective supply chain design. By taking a comprehensive view that addresses these core elements, businesses can significantly enhance the efficiency and resilience of their supply chains.

Supply Chain Design Objectives

From sourcing raw materials to the final delivery of products, a well-designed supply chain can be a game-changer in reducing costs and enhancing customer satisfaction. Specifically, there are key objectives that businesses aim to achieve in designing their supply chains. Achieving these objectives streamlines operations and gives companies a competitive edge. Understanding these objectives becomes indispensable for long-term sustainability and profitability as we navigate ongoing challenges such as labor shortages and technological advancements.

Right Sizing Inventory: High inventory levels can lead to increased holding costs, including warehousing, insurance, and the risk of obsolescence.

Reducing Reliance on Working Capital: Less money tied up in the supply chain means more funds are available for other business activities, such as research, development, or marketing. With the ongoing labor crisis showing no signs of slowing, the increased availability and reduced cost of automation present opportunities to optimize your current workforce.

Increasing Transparency: Transparency is crucial for tracking and traceability, helping to identify inefficiencies and bottlenecks in the supply chain.

Identifying Cost-Saving Opportunities: Operational efficiencies can translate directly into a more competitive pricing strategy.

Previously driven by the need for basic logistics and inventory control, today’s supply chain design focuses on a complex interplay of elements—ranging from network configuration and sourcing to real-time data analytics and risk mitigation. In this ever-evolving landscape, businesses aim not just to survive; they aim to thrive by optimizing various core elements and objectives. This comprehensive approach doesn’t just add efficiency—it builds resilience and competitive advantage, making it an essential strategic activity in today’s business environment.

Importance of Modeling and Simulation in Supply Chain Design

The role of modeling and simulation in supply chain design cannot be overstated, especially in an era characterized by rapid change and increasing complexity. Businesses can enact scenario management tailored to their unique processes and preferences by employing robust supply chain design solutions like GAINS. The emphasis is on making agile decisions—ones that can be implemented quickly yet are backed by data and analytics. This fusion of flexibility and confidence is invaluable, enabling companies to navigate a fluctuating business landscape while minimizing risks and capitalizing on opportunities. The key to this agility lies in the advanced software tools and simulation methods at decision-makers disposal.

GAINS, for instance, allows companies to use current data that reflect today’s business and economic environment, thereby ensuring that any simulations or models generated are both timely and relevant. Furthermore, the software offers continual, actionable results, meaning that insights can be put into immediate action, creating unparalleled time to value. By using these state-of-the-art technologies for scenario planning and optimization, businesses are better equipped than ever to make complex supply chain decisions. The result is a supply chain design responsive to current market conditions and robust enough to adapt to future changes.

Case Studies from GAINS Design Customers

Two large industrial product companies merged and needed to optimize their inter-branch supply chain network post-merger with a combined network of 100+ branch locations. The companies had overlapping territories and supply chains in most areas of the United States. Each company had a complex array of truck & rail transportation lanes & shuttles to consider. The global distributors asked for a model of their network to be built and identify critical areas for savings.

GAINS built & exercised a network design model to optimize the combined network of the 100+ branch locations. Combining the two companies allowed for economies of scale in inter-branch & inbound transportation (e.g., leveraging rail). GAINS identified over 7% savings in the network

A major Canadian retailer operating over 700 locations across multiple provinces needed to develop a comprehensive long-range distribution network plan. Since the company has been growing by acquisition over the last ten years, there were several distinct banners to consider, each with its own service and flow path requirements. Also, the retailer’s distribution network included over 35,000 SKUs, with some categories of SKUs requiring complex handling constraints, including federally regulated items.

GAINS developed a comprehensive distribution network plan and built the retailer’s large model, including the critical flow path requirements and complex handling constraints. Using cloud-enabled parallel solving, GAINS solved the large model quickly, helping the retailer realize more than 15% savings over the incumbent network by consolidating facilities into larger, automated facilities.

In conclusion

The complexities of modern supply chain design can be navigated effectively through a keen understanding of its core elements and objectives. As we’ve seen, technological advancements have become indispensable in achieving agility, efficiency, and sustainability. Tools like GAINS allow businesses to make real-time data-backed, actionable decisions, contributing to significant operational savings, as evidenced by real-world case studies. By aligning with critical objectives such as optimizing inventory, reducing working capital, and increasing transparency, companies can respond effectively to present-day challenges and future-proof their operations for long-term sustainability and profitability.

Embracing a comprehensive approach to supply chain design is no longer optional—it’s a business imperative.

Listen to our GAINS On Podcast with Matt Morton

Additional Reading

Supply Chain Design: Harnessing the Power of Cloud-Native Technology

The Power of Continuous Inventory Right-Sizing: Optimizing Supply Chains in an Uncertain World