Inventory Optimization

GAINS Inventory Optimization Software: Right-size inventory to free working capital.

Unlock higher-quality, more timely insights that consider a comprehensive set of cost, supplier, demand, and lead-time variabilities to reduce your inventory investment.

Every SKU matters.

Determine optimal stocking level for every SKU by location.

Our inventory optimization tool uses sophisticated analytics to achieve optimal service levels by embracing variability in demand forecasts, lead times, supply yields and ordering cycles — resulting in fewer lost sales and stockouts while maximizing profits.

Identify the ideal service level for each item according to your business strategy.

Maximize supply chain performance.

GAINS helps you manage variability and uncertain demand with multi-echelon inventory optimization (MEIO) to cost-effectively right-size your inventory and manage risk.

Core Features: what’s included

Inventory policy optimization

Precisely achieve targeted service levels by comprehensively managing sources of variability.

Service level optimization

Automatically determine service levels uniquely for each item to achieve an aggregate target while achieving the business objective.

Multi-echelon stocking policies

Determine whether or not to stock an item and at what service level, solving for interdependencies within a BOM or distribution network.

Automated multi-echelon modeling

Dynamically determine the profit-optimal stocking strategy for each SKU in the BOM.

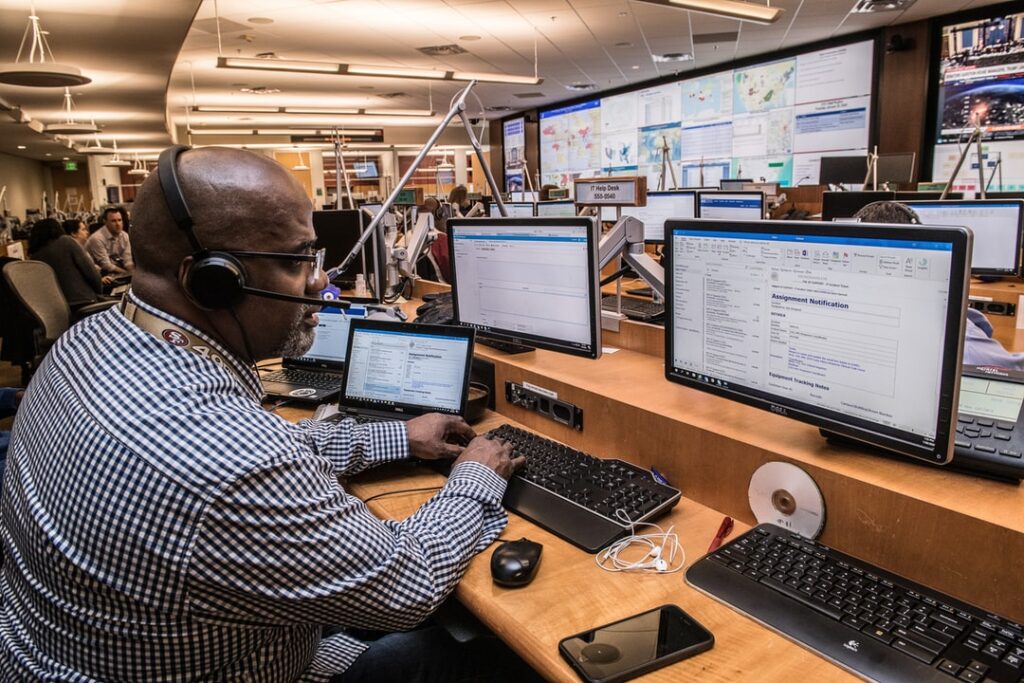

GAINS DEO platform overview

Learn more about DEO

Frequently asked questions

How does GAINS software help supply chain managers in reducing inventory carrying costs?

GAINS software provides powerful tools and insights that help supply chain managers reduce inventory carrying costs through a combination of advanced analytics, real-time data, and strategic optimization techniques. Here’s how:

- Demand Forecasting Accuracy: GAINS improves demand forecasting accuracy by leveraging advanced analytics and AI. This ensures that inventory levels align with actual demand, reducing excess stock and minimizing carrying costs.

- Dynamic Safety Stock Management: Our software dynamically adjusts safety stock levels to ensure you have the right amount of buffer stock to manage all of the sources of variability in your supply chain. This optimizes inventory buffers, preventing overstocking while ensuring sufficient supply to meet customer needs.

- Network-Wide Inventory Visibility: GAINS provides real-time visibility into inventory levels across the entire supply chain. This allows managers to make informed decisions about stock transfers, reordering, and demand fulfillment, reducing unnecessary inventory buildup.

- Optimized Replenishment Strategies: We implement optimized replenishment strategies that consider lead times, order quantities, and supplier reliability. This ensures timely restocking with minimal inventory holding, reducing carrying costs.

- Advanced Inventory Segmentation: GAINS software segments inventory based on various criteria, including demand patterns, product lifecycle, and profitability. This targeted approach helps prioritize high-value items and manage slow-moving stock more effectively.

- Continuous Monitoring and Alerts: Our software continuously monitors inventory levels and provides alerts and recommended actions for potential issues such as stockouts or excess. This proactive approach enables timely interventions to maintain optimal inventory levels.

- Scenario Analysis and Simulation: GAINS allows managers to perform scenario analysis and simulations to understand the impact of different inventory strategies. This helps identify the most cost-effective approaches to inventory management.

- Collaboration and Integration: Our software integrates seamlessly with other systems and promotes collaboration across departments. This ensures that inventory decisions are aligned with overall business objectives and operational constraints.

Can GAINS optimize inventory across a global supply chain with varying lead times and service requirements?

- Global Visibility: GAINS provides comprehensive visibility into inventory levels down to individual SKUs by location (SKUL) and movements across all locations in your supply chain. This real-time insight enables better coordination and informed decision-making to optimize inventory distribution.

- Advanced Analytics: Our advanced analytics tools account for the complexities of global supply chains, including varied lead times, transportation modes, and demand variations by region. This allows supply chain professionals to create precise and efficient inventory strategies.

- Lead Time Management: GAINS accurately models lead time variance across different suppliers and regions. Incorporating these lead times into our algorithms ensures that inventory levels stay balanced and aligned with service requirements.

- Service Level Optimization: We optimize inventory levels for all markets and products to meet your specific service requirements. This ensures high service levels and customer satisfaction while right-sizing inventory and carrying costs.

- Dynamic Replenishment: GAINS implements dynamic replenishment strategies that adapt to changes in demand and supply conditions. This flexibility ensures timely restocking and reduces the risk of stockouts or overstock situations.

- Scenario Planning and Simulation: Our software allows for scenario planning and simulations to evaluate the impact of various factors on your inventory performance. This helps to develop robust strategies to manage uncertainties and disruptions in the global supply chain.

- Integrated Supply Chain Solutions: GAINS Connect integrates seamlessly with other supply chain management systems, ensuring smooth data flow and collaboration across your supply operation. This holistic approach enhances overall supply chain efficiency.

- Continuous Improvement: We continuously monitor and analyze inventory performance, providing insights and recommendations for ongoing optimization. This commitment to continuous improvement ensures that your inventory strategies remain effective amid continual uncertainty.