When inventory management falters, so does the rest of your operation. Supply chain disruption in the wake of COVID-19 restrictions has underscored the importance of swiftly overcoming inventory management challenges. If products do not reliably get from A to B, it threatens the sustainability of any business.

Despite the inherent complexity of managing inventory, inaccurate demand forecasts, limited visibility, and inventory errors aren’t inevitable. If your organization regularly battles any of the challenges below, rest assured that there’s a way out with better decision-making and better insights.

Ten Common Inventory Management Challenges Every Business Can Do Without

1. Overstocking & Excess Inventory

Too much inventory leads to increased costs. If a business has to rent additional storage to hold excess stock or needs to write off slow-moving products that have become obsolete, profitability will suffer. A Massachusetts Institute of Technology (MIT) Center for Transportation & Logistics study found that excess inventory level is a major problem for many businesses and can lead to significant financial losses. Rising opportunity costs, and depreciation is not what any organization’s bottom line needs.

The restructuring of Ralph Lauren a few years back illustrates the lamentable financial impact of overstocking, in Ralph Lauren’s case, as a result of slow lead times. While inventory grew by 26% over three years, sales saw only a 7% increase. The result: profits plummeted by 50%.

2. Understocking & Stockouts

The consequences of understocking and stockouts reverberate throughout the supply chain, whether due to delivery delays, production issues, or forecasts gone wrong. Lost sales and disappointed customers inevitably damage a business’s reputation. A business that consistently fails to meet delivery deadlines will be seen as unreliable and lose customers who can easily buy from a competitor.

3. Inventory Errors

Managing a complex distribution network via spreadsheets and other manual processes rather than an inventory management system does not set any business up for success. While well known as an inefficient process, manual documentation is still a surprisingly common cause of inventory errors, including obsolete inventory, an incorrect inventory count due to misplaced items, or overall inventory accuracy.

Other inventory control issues stem from:

- Inaccurate forecasting: Poor demand forecasting is often to blame, whether it results in excess inventory or stockouts.

- Lack of real-time data: Like yesterday’s news, yesterday’s data isn’t beneficial. The ability to access real-time inventory data is a necessity to reduce the risk of errors.

4. Lack of Visibility

You can’t fix a problem you don’t know about. Unknown physical inventory levels due to a lack of real-time inventory visibility can make management and decision-making difficult. That, in turn, results in mounting challenges:

- Inability to accurately forecast demand: Forecasting based on obsolete data and guesswork is bound to fail, forcing the business to pay the price in stockouts or excess inventory.

- Inefficient use of resources: Without visibility into inventory levels, a business cannot know which products are moving quickly and which ones see little demand. As a result, the company may keep producing items that are not needed while failing to meet the demand for others.

- Poor customer service: When inventory management falls into disarray, the end customer eventually suffers, leading to frustration and lost trust. This creates a stressful, difficult situation for your customers and frontline employees, further risking the quality of your customer experience.

5. Inaccurate Demand Forecasts

Demand planning and forecasting are at the core of good inventory management, but they are also notoriously challenging to get right. The myriad of moving parts—sudden changes in consumer preferences, seasonal fluctuations, unexpected competition, and rising inflation—demand a lot from the inputs and the inventory management system that creates forecasts. However, businesses that widely miss the mark will pay a high price.

6. Complex Global Supply Chains

Navigating the intricate web of the global supply chain is a formidable challenge involving multitudes of stakeholders across different continents and operating under diverse regulations in distinct environments.

- Risk of Disruptions and Delays: Modern supply chains are vulnerable due to their extended and interconnected nature. The continual risks of natural disasters, political instability, trade disputes, or pandemics increase the risk of disruptions and delays.

- Logistical Complexities: Managing logistics across borders involves dealing with various transport modes and carriers, fluctuating shipping costs, and potential delays due to customs clearance or geopolitical issues

- Currency Fluctuations and Financial Risks: Dealing with multiple currencies can expose businesses to financial risk due to currency fluctuations. If not managed effectively, these can impact the cost of goods and profitability.

7. Regulatory Compliance and Sustainability Issues

Businesses must navigate a web of regulations that vary by country and region. These regulations can pertain to a wide range of issues. Moreover, there is an increasing emphasis on sustainability in supply chains, which adds another layer of complexity.

- Supply Chain Transparency: Transparency is critical to compliance and sustainability. Businesses must clearly understand where and how their products are made and by whom. This includes scrutinizing suppliers and ensuring they adhere to the same standards and practices.

- Product Lifecycle Management: Complying with environmental regulations often means taking responsibility for the entire lifecycle of a product. This includes considering the ecological impact of products from creation to disposal and sometimes involves recycling or taking back products at the end of their life.

8. Rapid Technological Changes

The swift evolution of technology in the supply chain presents opportunities and challenges. On the one hand, advancements provide innovative solutions for improving inventory management software efficiency, transparency, and decision-making. On the other hand, continually trying to integrate new technologies into existing supply chain systems can be complex and resource intensive. This dichotomy makes navigating technological changes a critical yet challenging aspect of modern supply chain management.

9. Customer Demand Fluctuations

One of the most formidable challenges faced by businesses is fluctuating customer demand. This volatility is often driven by rapidly changing consumer preferences, significantly influenced by social trends, market shifts, and global events. The unpredictability of these factors makes it exceedingly difficult for businesses to forecast demand and develop a successful inventory management process.

- Real-Time Demand Sensing: Traditional demand forecasting and inventory management techniques, often based on historical data, struggle to keep pace with these rapid changes. There’s a growing need for real-time demand sensing – a capability to monitor current market conditions and adjust forecasts and inventory levels accordingly.

- Supply Chain Responsiveness: Fluctuating demand requires a supply chain that is efficient and highly responsive. Businesses must be able to scale operations up or down swiftly in response to changing demand patterns.

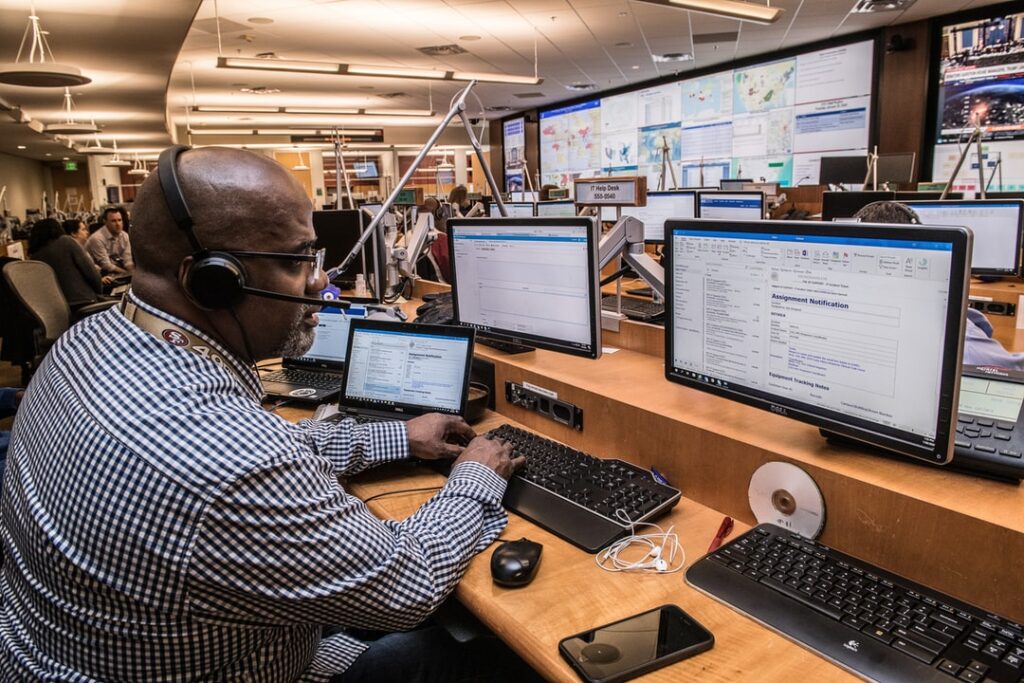

10. Cybersecurity and Data Protection

Beyond an inventory management challenge, supply chains have become more digitized and reliant on big data, and the risk of cyber threats and the need for robust data protection grows. GAINS’ platform can offer secure data handling and advanced cybersecurity measures, ensuring that sensitive supply chain data remains protected against breaches and cyber-attacks.

The Way Forward

Many businesses will incur any or all of the above inventory management challenges. While the VUCA (volatility, uncertainty, complexity, and ambiguity) environment of the last few years will likely continue indefinitely, organizations can weather the storm successfully. The most effective way to combat the chaos is to partner with an experienced provider like GAINS. By addressing these challenges through the lens of GAINS’ innovative approach, businesses can effectively navigate the complexities of modern supply chains and maintain a competitive edge.

Here’s how GAINS addresses each challenge:

- Overstock: GAINS prevents overstock by developing independent demand forecasts for each Stock Keeping Unit Location (SKUL). It plans inventory replenishment based on the actual forecasted demand rather than historical percentages. GAINS creates simulated lead time forecasts using historical demand and its sophisticated forecast model algorithms.

- Understock: GAINS facilitates accurate projections of inventory positions over a certain time frame, combining inventory management policies and procedures with automated analyses. GAINS uses AI to optimize inventory management and prevent understock. Considering their dependencies, it assigns service levels to each SKUL to minimize the total stocking cost. It provides tools such as a Relationship Graph and a Variance Drivers table, which allow users to review the components driving an item’s supply variability.

- Inventory Errors: The system reduces reliance on manual documentation and outdated systems, minimizing the risk of inventory planning errors through automation and accurate record-keeping.

- Lack of Visibility: GAINS enhances supply chain visibility, offering real-time data and analytics to make informed decisions and more effective inventory management.

- Inaccurate Demand Forecasts: GAINS improves the accuracy of demand forecasts by leveraging sophisticated algorithms and AI. GAINS suggests a replenishment action schedule to the planner, helping maintain inventory balance and desired customer service level

- Complex Global Supply Chains: GAINS provides real-time insights and predictive analytics to navigate the complexities of global supply chains. It offers solutions for optimizing route planning, inventory cost, and supplier selection, ensuring efficiency and resilience.

- Regulatory Compliance and Sustainability Issues: The GAINS Performance Optimization Platform helps manage compliance with regulations and sustainability standards. Its data-driven approach offers visibility into supply chain practices, ensuring environmentally sustainable and ethical sourcing.

- Rapid Technological Changes: GAINS’ composable architecture allows businesses to adapt to new technologies seamlessly. It integrates the latest advancements in supply chain technology, ensuring businesses stay at the forefront of innovation.

- Customer Demand Fluctuations: GAINS utilizes AI and ML to analyze real-time market trends and consumer behavior. This allows for more accurate forecasting and effective inventory management in response to changing customer preferences.

- Cybersecurity and Data Protection: GAINS practices secure data handling practices and advanced cybersecurity measures, protecting sensitive supply chain data from breaches and cyber-attacks.

There are a myriad of challenges businesses face in inventory management, particularly in the ever-changing global supply chain landscape. From dealing with the complexities of global logistics and regulatory compliance to adapting to rapid technological changes and fluctuating customer demands, the scope of these challenges is vast and varied. However, the focus shifts to how GAINS, with its cutting-edge AI and ML technologies, provides robust solutions to these issues.

GAINS offers real-time insights, predictive analytics, and efficient management strategies to enhance supply chain resilience and adaptability, and overall outcomes. By leveraging GAINS’ extensive expertise and innovative algorithms, businesses can not only navigate these challenges but also transform them into opportunities for growth, ensuring operational efficiency and sustained competitiveness in the dynamic global market.

Contact GAINS about designing the inventory optimization that’s right for you.

Request a Demo NowMore Resources