The chaos of the pandemic years and the resulting supply chain crisis have made predicting customer demand more challenging. As you undoubtedly have seen, many companies are currently experiencing “ The Bullwhip Effect .” So, what is the ‘bullwhip effect,’ and why is it a problem right now? The bullwhip effect is a scenario in which temporary surges in retail demand get amplified by upstream manufacturers and suppliers, who rapidly increase production past the level that consumers can support. Eventually, companies find themselves with more excess inventory than they can sell based on consumer demand, and what started as a goods shortage ends up as a goods surplus. Some businesses, like the US’s second-largest importer of goods, Target , have fallen victim due to the bullwhip effect. In contrast, others, including Graybar, have used data from across the organization to manage inventory levels successfully.

The Inventory Bullwhip Effect Has Become a Trillion-Dollar Problem?

The bullwhip effect creates demand distortions, resulting in out-of-stock items, misaligned inventory levels, and lost profits from deep discounts on overstocked ones. Retail losses alone cost the global economy $1.1 trillion annually. Companies are losing money fast as a result of demand and forecast inaccuracies.

Here are a few recent examples of company losses due to the bullwhip effect:

- Target’s stock is down 14% in June 2022 due to inflation and “historic highs with inventory levels,” according to Target CEO Brian Cornell.

- The Gap shares fell nearly 20% in extended trading. CEO Sonia Syngal told CNBC, “Shoppers also have quickly shifted from buying active clothes and fleece hoodies — to looking for party dresses and office clothes.”

- American Eagle Outfitters saw their total ending inventory at cost rose 46 percent to $682 million.

Unfortunately, the bullwhip effect is almost inevitable when using traditional supply chain management methods, namely Excel. Spreadsheet errors can cost businesses billions, according to a financial modeling company F1F9, which estimated that 88 percent of all spreadsheets have errors. So how can companies help reduce the obligatory discounting, overstock, storage costs, and outright waste that the bullwhip brings?

Greater Supply Chain Visibility Helps to Avoid Excessive Inventory

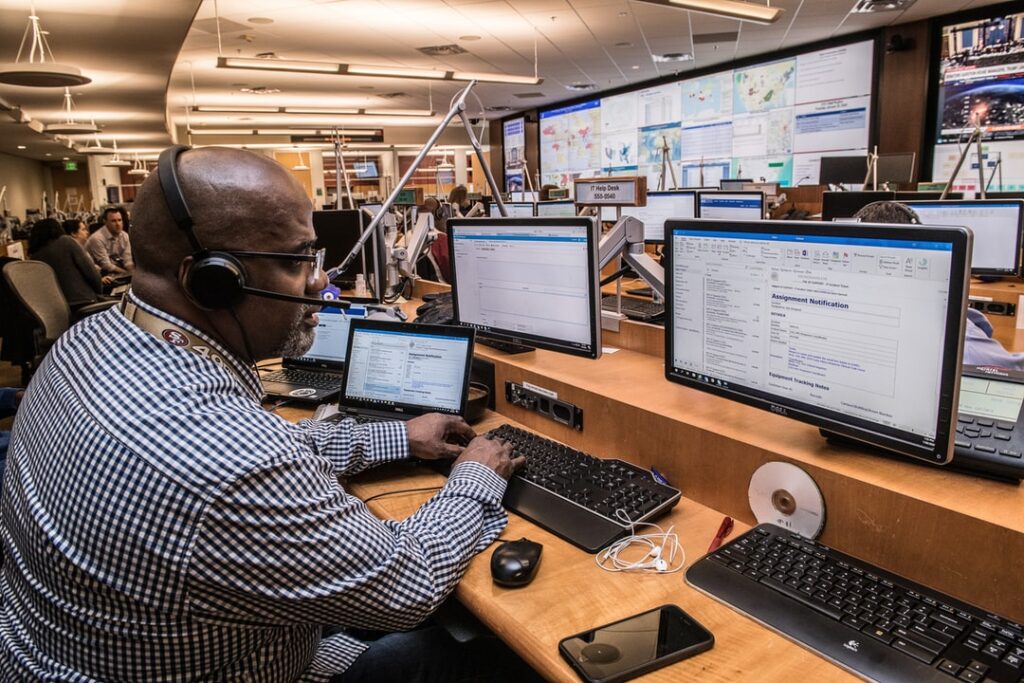

One approach to prevent the bullwhip effect on excess inventory or safety stock is to improve supply chain visibility. Monitoring all aspects of your supply chain, from manufacturing to purchasing, from warehousing to transportation, through sales and customer service, reduces surprises. After all, you can’t fix what you can’t see. With added supply chain visibility, your teams aren’t caught flat-footed when swings in the supply chain happen, or they have adequate time to form and execute an alternative plan (AKA Plan B).

Having visibility across the supply chain network ensures that businesses know when order variabilities occur, can see them coming, and can create a plan to mitigate the impact on service levels, production schedules, missed sales, and much more.

Get Ahead of Inventory Issues Before They Arise

Another tried and tested method is to get ahead of the problem with inventory optimization . Graybar, a leading electrical distributor and a long-time GAINS customer, has used this strategy since the early days of COVID to control inventory and avoid overstocks.

Using GAINS’ automated inventory optimization algorithms, Graybar analyzed a comprehensive set of cost and source variabilities across their supply chain. They addressed or removed potential unknowns, or bullwhips, using automation to manage every SKU, by every location, across the supply chain. This approach empowered them to make the right decisions to:

- Meet service-level expectations

- Correct demand forecast and planning errors

- Manage lead-times

- Maintain profitability

Mike Polansky, Director of Planning and Procurement at Graybar, said, in a recent video interview :

“We needed something that is designed around inventory management, that takes into consideration profitability. We want to have fuel [inventory] to feed the sales engine at Graybar and not just have boxes sitting there, not making a profit for the company. With GAINS, Graybar has a robust planning platform that drives informed economic buying decisions to provide great service even in times of significant volatility.”

They also recognized that having the right data is needed for many more organizational roles, especially during times of high variability. Graybar’s Polansky goes on to share the importance of data across the organization when managing inventory:

“It goes from the CFO to the inventory planner, all utilizing GAINS to make sure the proper decision is being made. [This is true] even in volatile markets with crazy lead times, not knowing when it is coming in from week to week, month to month, or for some products, it’s well over a year. You have to have the data to be able to [manage] that.”

Being a Good Supply Chain Partner is More Than Just Spending Money

Lastly, excessive overstock hurts your bottom line and raises storage fees and insurance costs, but it can also affect your trading partner relationships with suppliers. Ordering and then canceling can harm critical business relationships with your suppliers. Being a steady and predictable customer to your suppliers helps them in the long run, allowing them to predict customer demand for their own business better, fostering a better business relationship, and lessening your contribution to the inventory bullwhip effect. You are more likely to receive preferential treatment as an organization that doesn’t contribute to chaos and openly communicates with trading partners about changes.

Open communication and collaboration are critical to a successful supplier relationship and reducing the likelihood of the bullwhip effect. Savvy organizations understand when buyer and supplier communities collaborate, they often find ways to mitigate the risk of future demand fluctuations and unlock significant new sources of value that are mutually beneficial beyond just the typical quid pro quo. As McKinsey puts it: Companies with advanced procurement functions can take an integrated approach to supply chain optimization, redesigning their processes together to reduce waste and redundant effort or jointly purchasing raw materials.

Is the bullwhip effect impacting your business? Don’t let customer demand and supplier variability wreak havoc on your supply chain management. Learn how the GAINS Inventory Optimization and Demand Planning and Forecasting solutions can provide the necessary demand signals, lead time analysis, visibility, optimization, and supply chain management. Visit https://gainsystems.com to request a demo.