Design Smarter. Adapt Faster. Win in Uncertainty.

There’s a New Standard in Design

Build resilient, high-performing supply chains with GAINS’ AI-powered, simulation-backed design solution that transforms variability into a competitive advantage.

Why Design Matters More Than Ever

It’s time to break away from outdated methods.

Today’s supply chains face relentless disruption—tariff wars, geopolitical shifts, extreme weather, shifting demand, and global competition. Yet most networks were designed in a different era, under static assumptions that no longer hold up.

GAINS empowers companies to build dynamic supply chains that thrive in uncertainty. Design is no longer a one-time activity. It’s a strategic, continuous discipline that enables you to proactively plan for what’s next and understand the cause and effects of your decisions.

Design for Variability and Risk

Most design platforms treat uncertainty as an afterthought. GAINS bakes it into the process. Our Risk Adjusted Design (RAD) capabilities account for real–world fluctuations from the start—so

you’re not just prepared for change, you thrive in it.

Outcome: Increased resilience, reduced cost-to-serve, better customer outcomes.

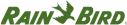

Simulation at the Core

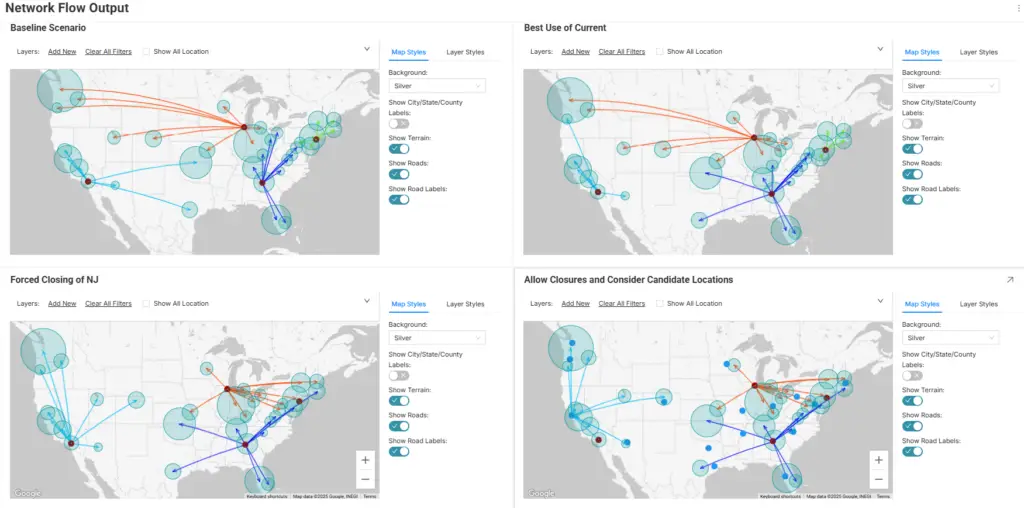

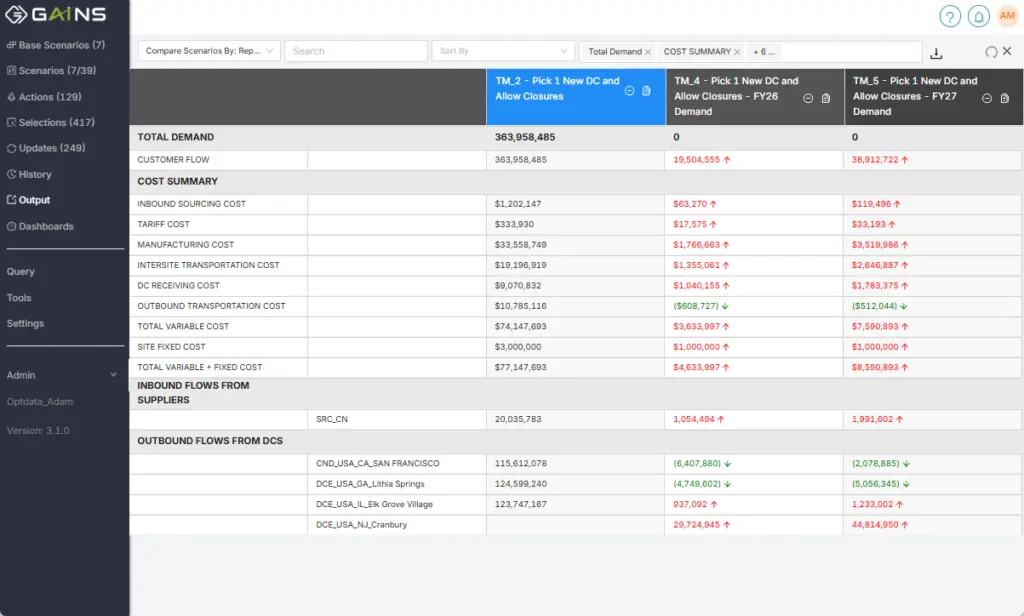

GAINS uses discrete-event simulation to model supply chains in lifelike detail. Test “what if” scenarios before you invest. Understand bottlenecks, risk exposure, and service impact—all before you break ground or reroute a truck.

Outcome: Confident decision-making with scenario clarity.

Unified Design + Planning + Execution

We don’t just stop at design. GAINS integrates design insights directly into planning and execution workflows. No handoffs, no siloed strategies—just a connected, continuously improving system.

Outcome: Immediate implementation, faster time-to-value.

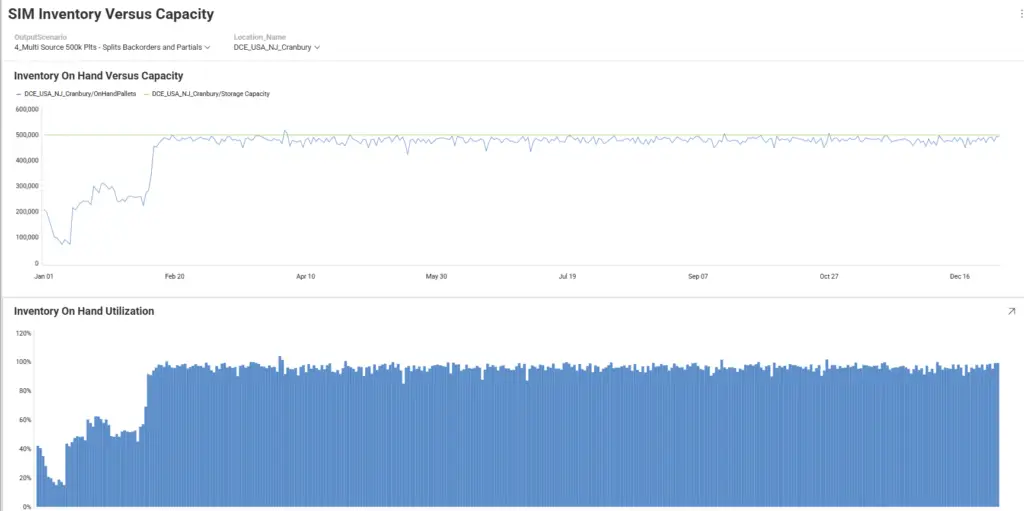

AI that Actually Works

Forget the buzzwords. Our AI supports real decisions. From probabilistic modeling and route optimization to a smart assistant that can suggest scenarios or run a model for you—GAINS DEO AI Agent is your copilot in building and maintaining a resilient supply chain.

Outcome: Faster solve times, reduced manual effort, scalable design insights.

Made for Humans, Not Just Modelers

Most platforms require PhDs in modeling. GAINS empowers your supply chain business experts with intuitive tools, natural language support, and embedded AI recommendations. No steep learning curve. Just smart, fast outcomes.

Outcome: Democratized design that scales across the business.

Decision Engineering & Orchestration (DEO): The Brain Behind Better Decisions

GAINS doesn’t just help you build models—we help you make better decisions. Our Decision Engineering and Orchestration (DEO) process and architecture layer connects design, planning, and operations to business priorities like cost, service, and risk. DEO doesn’t just surface insights—it guides decisions, automates scenario testing, and ensures every outcome aligns with your strategic objectives.

Outcome: High-fidelity, high-impact decisions made faster, with less guesswork.

Designed for What’s Next

We’re proud to be named a technology leader in the 2025 SPARK Matrix™ for Supply Chain Network Design. It’s a big win—not just for us, but for every business using GAINS to build smarter, more resilient supply chains.

Our Engagement Offerings

Consulting

End-to-End or partial ownership: guide process, modeling, analysis, and conclusions

Design as a Service

Outsourced design team with dedicated GAINS resources

Staff Augmentation

Contract GAINS professional to work under customer’s direction with guidance from GAINS

Advisory

Periodic check-ins, coaching, or quality assurance as deemed necessary from customer. Block of hours used as needed with no specific deliverables from GAINS

Training

Training sessions targeted at learning how to use the software. Processes and methodologies associated with conducting supply chain design.

Why Choose GAINS for Design?

They're Not Like Us

Others say AI; GAINS – It’s in our name.

Our AI

Probabilistic design, simulation, learning from prior runs, genetic routing algorithms, natural language bots.

Their AI

Mostly buzzwords. Workflow builders dressed up as intelligence.

While others talk a good game, GAINS delivers repeatable business results through true design intelligence, not smoke and mirrors.

The world won’t stop changing.

Why should your supply chain?

Schedule a demo and see how GAINS can help you move from reactive to resilient—by design.

Decisions We Power

Tariff Impact Analyzer

Assess how shifting trade policies and tariffs affect your total landed cost, supplier strategy, and logistics flows.

- Simulate different tariff scenarios to uncover vulnerabilities and high-risk trade lanes

- Evaluate alternative sourcing and routing strategies to minimize cost and mitigate disruption

- Visualize impacts across your network and align stakeholders around the best path forward

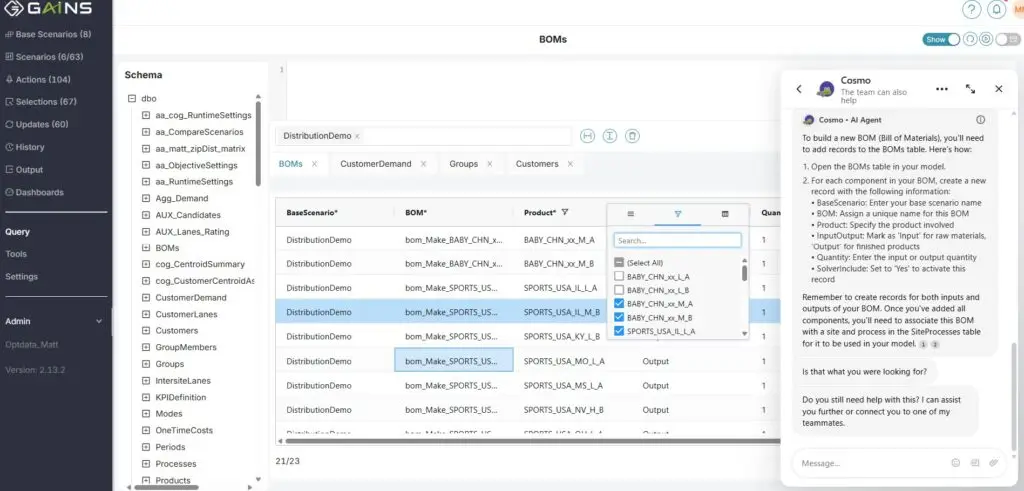

Network Optimization

Identify inefficiencies and model cost trade-offs to design the lowest-cost, highest-performing network.

- Analyze shipment history to identify the non-optimal flows

- Evaluate new production, distribution, and transportation options to reduce cost

- Model impact of multiple cost variables to establish lowest total landed cost while respecting constraints

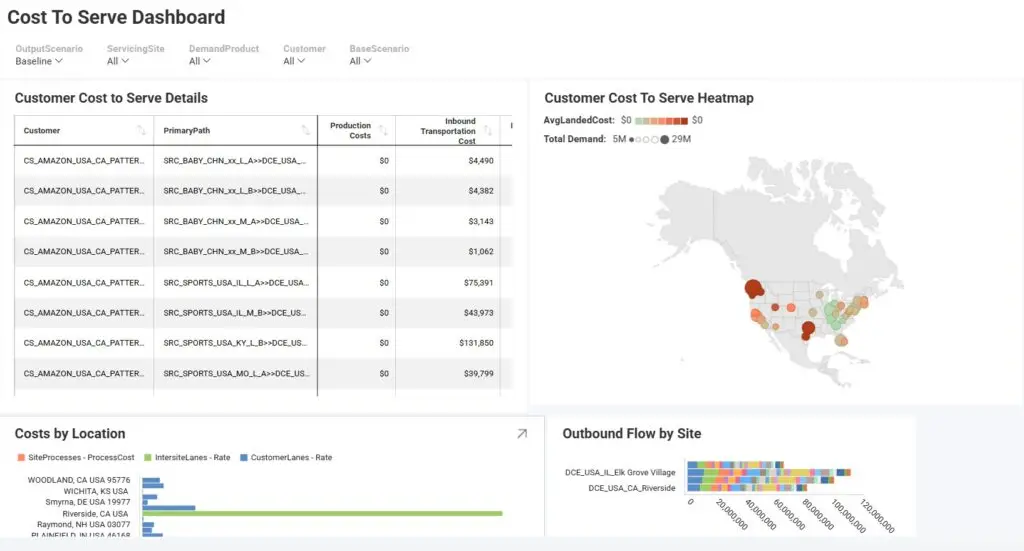

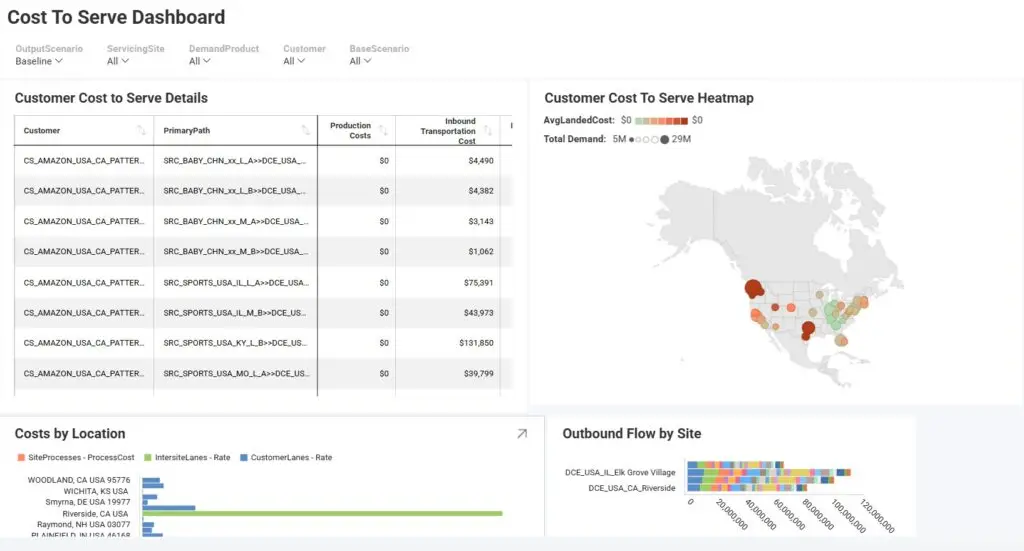

Cost-to-Serve

Balance cost, service, and risk by analyzing every supply chain path a product takes from vendor to customer.

- Evaluate total landed cost by factoring in inventory, import, transportation, and allocated fixed distribution costs

- Analyze profitability at the product, customer, or facility level to uncover margin improvement opportunities

- Use per-unit cost and revenue insights to optimize network design and eliminate unprofitable configurations

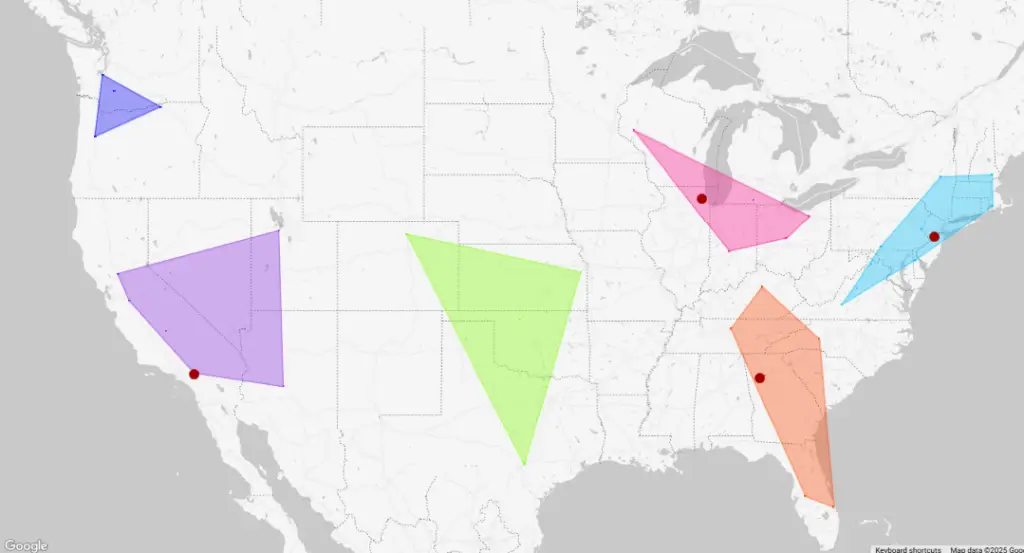

Greenfield Optimization

Determine where to expand, consolidate, or invest with data-backed clarity.

- Answer facilities questions, “How many should we have?” & “Where should they be?”

- Plan for expansions in volumes or into new geographical areas

- Optimize facility footprint for service or cost

- Optimize existing network footprint to identify savings and/or service improvements

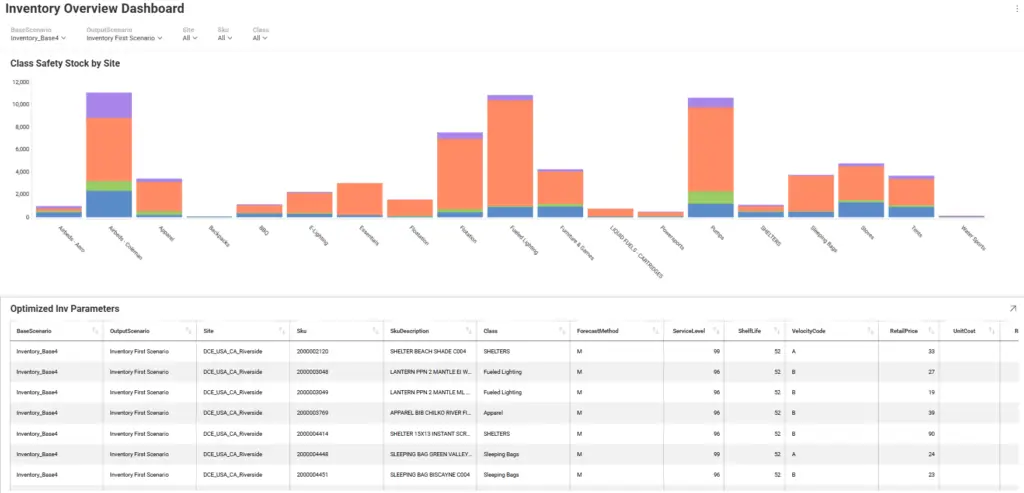

Inventory Strategy Design

Set the right policies based on actual demand patterns and service targets.

- Combine design and planning data to shape smarter inventory strategies

- Align stocking locations and service levels with real demand patterns

- Automatically generate policies like reorder points and order-up-to levels by SKU and location

- Ensure the right inventory is in the right place to balance cost and service

M&A Synergy Modeling

Simulate how to best combine operations, assets, and networks.

- Validate potential changes and test theories in a digital sandbox

- Sequence integration priorities and create a plan based on feasibility & efficiency gains

- Create combined network synergies

- Overlay the combined assets & operations of each business

Long-Range Scenario Planning

Build multi-year strategies and phased roadmaps that evolve over time.

- Evaluate multi-year investment strategies under different market, demand, or geopolitical conditions

- Stress-test your network against extreme scenarios to uncover vulnerabilities and resilience gaps

- Align supply chain design with corporate growth goals, M&A plans, and sustainability targets over time

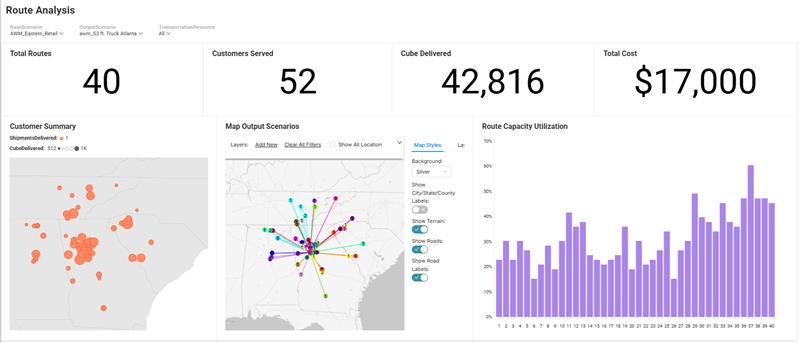

Vehicle Route Optimization

Optimize routes, modes, and carriers with our genetic AI algorithms. Perform strategic planning for transportation fleets and/or 3rd-party providers. Identify cost reduction opportunities, including:

- Consolidation of multi-stop pickup or delivery routes

- Reduction of empty miles

- Route sequencing and asset assignment

- Shipment balancing and service frequency insight

- Evaluate underlying cost structures of existing transportation network

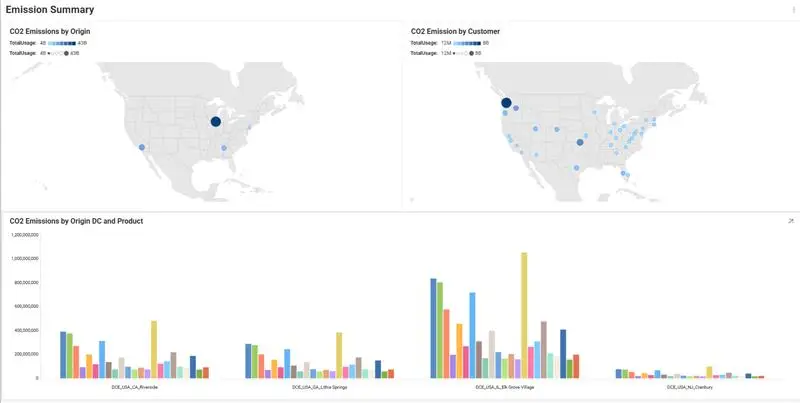

Sustainability Modeling

Visualize tradeoffs between emissions, cost, and service. Hit your CO2 targets without breaking the bank.

- Enable smart sustainability strategies

- Quantify financial impact of achieving sustainability goals

- Model & visualize emission levels based on various supply chain designs

- Model ramp up of sustainability efforts over a multi-year initiative

What Makes GAINS Unmatched

Composable and Future-Ready

Our composable architecture lets you evolve your design tech as new tools, solvers, or data streams emerge. You’re never locked in—just always ahead.

Built to Scale

Cloud-native and hyper-performant, GAINS lets you run complex, multi-scenario analyses in real time. Need to test 5,000 combinations overnight? No problem.

Proven Results

- 15% cost savings by consolidating distribution for a Canadian retailer

- 20% lead time reduction by redesigning inbound flows for an industrial manufacturer

- Multi-tier network enabling scalable expansion for a national food chain

Not Just Software. A Strategy Partner.

Our experts have helped optimize hundreds of networks. We don’t just hand over the tech—we co-design strategies, run simulations, and ensure implementation sticks.

CONNECTING DECISIONS TO OUTCOMES

Answering the 'What Ifs' That Drive Supply Chain Strategy

Real-World Impact

Proven Success Stories

Former Optilogic customer, ACR- a leading manufacturer and distributor in the food service industry, achieved notable improvements in service levels, cost efficiency, and inventory management.

Enhanced fill rates to 98% from the mid-70% range, ensuring customers received complete orders promptly.

Reduced outbound freight and warehouse expenses by 27% through optimized inventory placement and smarter route planning.

Achieved over 95% fulfillment from default locations, reducing the need for split shipments and improving customer satisfaction.

Decreased overall inventory levels by 25% while simultaneously experiencing sales growth, leading to improved cash flow and reduced holding costs.

Explore news and insights to drive supply chain outcomes.

For years, lead time has been treated as a fixed number. One field in the [...]

Customers achieving significant performance improvements across their supply chains drive record adoption of the GAINS platform and leads to strongest quarter in company [...]

If you talk to most planners, you’ll hear the same story: too much time spent [...]

The world won’t stop changing.

Why should your supply chain?

Schedule a demo and see how GAINS can help you move from reactive to resilient—by design.

Frequently asked questions

How does GAINS ensure that supply chain design aligns with our business objectives?

At GAINS, we understand that every business has unique goals and requirements. To ensure our supply chain design aligns with your business objectives, our dedicated software implementation team follows a comprehensive and collaborative approach guided by the GAINS P3 Methodology– New Window:

- Design : We meet with your team and thoroughly analyze your existing supply chain processes, future and current business goals, and market conditions. This helps us understand your specific needs and challenges.

- Configure We use advanced analytics and supply chain optimization tools to create tailored solutions that address your individual business requirements. Our designs are flexible and adaptable to change.

- Collaborative Approach: We work closely with your team throughout the design process. Regular consultations and close collaboration ensure that our solutions perfectly align with your strategic objectives.

- Enable: We design our solutions to deliver quick wins while establishing benchmarks that measure the project’s success at every stage. By incorporating these benchmarks, we ensure that our supply chain design continuously aligns with your business goals. This approach allows us to make data-driven adjustments as needed, ensuring sustained progress and long-term success.

- Monitor and Advise: Our commitment to continuous improvement means regularly reviewing and refining our supply chain designs to keep pace with evolving business needs and market dynamics. We offer flexible options to support your continuous improvement efforts: our design team can either consult with your internal team, providing expert advice and insights or take a more hands-on approach by managing the entire process for you. This ensures that your supply chain remains agile, up-to-date, efficient, and perfectly aligned with your strategic objectives, regardless of how market conditions or your business needs evolve.

GAINS helps you achieve operational efficiency, cost savings, and enhanced competitiveness in the marketplace.

Can GAINS help redesign our supply chain to be more resilient to disruptions?

- Risk Assessment: We conduct a comprehensive risk assessment to identify potential vulnerabilities in your supply chain. This includes evaluating supplier reliability, transportation risks, and market fluctuations.

- Diversification Strategies: To mitigate risks, we design diversification strategies that include multiple sourcing options, alternative transportation routes, and flexible production capabilities. This ensures that your supply chain can adapt quickly to unexpected changes.

- Advanced Analytics: Our advanced analytics tools provide real-time visibility into your supply chain operations. This enables proactive decision-making and rapid response to disruptions.

- Scenario Planning: We develop and simulate various disruption scenarios to prepare your supply chain for different risk factors. This helps in creating contingency plans that can be swiftly activated when needed.

- Continuous Monitoring: Our continuous monitoring services ensure that any emerging risks are identified early, allowing for immediate corrective actions. This ongoing vigilance helps maintain supply chain stability.

- Collaboration and Training: We work closely with your team to ensure they are equipped with the knowledge and tools needed to manage disruptions effectively. Training sessions and collaborative planning enhance your team’s resilience capabilities along with our in-app chat bot for users of the GAINS design solution.

By redesigning your supply chain with resilience in mind, GAINS helps you minimize the impact of disruptions and maintain smooth operations, ensuring business continuity and providing you with a competitive advantage.

Related Resources

Customer Success How ACR Achieved 98% Fill Rates And Reduced Inventory While Growing Sales Download [...]