In today’s manufacturing landscape, companies face increasing complexity, fluctuating demand, and the need for optimized supply chain operations. To transition from reactive to proactive planning, manufacturers can leverage advanced data analytics, machine learning, and adaptable strategies to enhance efficiency, reduce costs, and better allocate resources.

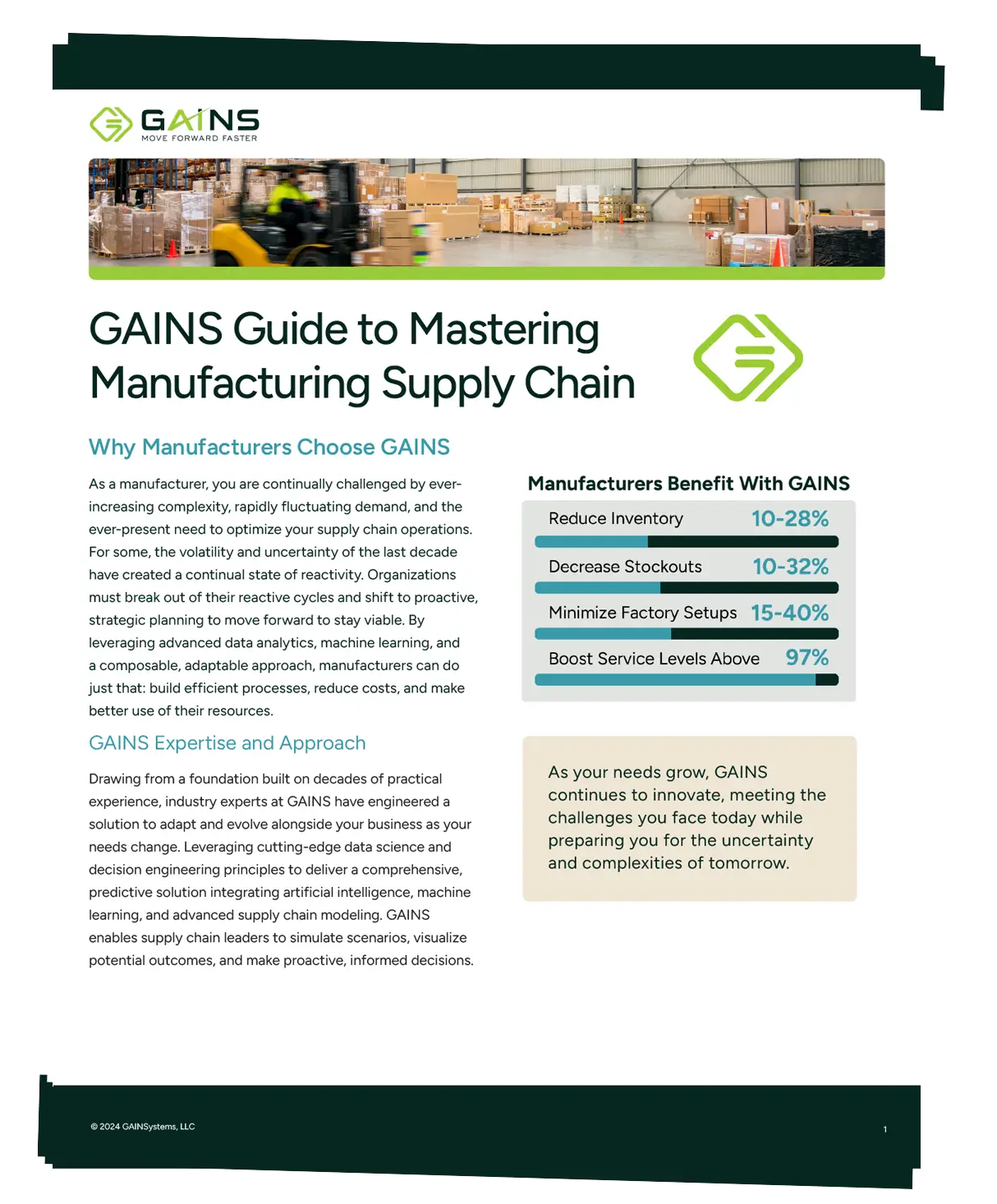

GAINS offers a comprehensive solution built on decades of practical experience, integrating artificial intelligence and advanced supply chain modeling. This platform enables leaders to simulate scenarios, visualize outcomes, and make informed decisions, fostering a resilient and agile supply chain. By optimizing inventory, forecasting demand, and aligning production with real-time data, GAINS empowers manufacturers to navigate uncertainties and maintain a competitive edge.

In This Guide, You Will Learn: