Inventory Optimization

GAINS Inventory Optimization: Engineered to Defy Disruption

Stock Smarter, Not Just More.

Design Your Supply Chain to Adapt in Real Time

Optimizing inventory isn’t about carrying less or more—it’s about making smarter decisions. But every choice comes with a trade-off. Do you stock more to avoid a stockout, or do you protect cash by tightening your policies?

This is where GAINS’ Decision Engineering & Orchestration (DEO) shines. Weigh the cost, risk, and service impact of every move, so you don’t have to guess which trade-offs matter most. With GAINS, you can balance them all—intelligently, dynamically, and on your terms. Engineer a dynamic, always-on, decision-ready system powered by GAINS DEO.

Driven by Your Priorities, Shaped by Your Strategy, Powered by GAINS

A System That Learns and Evolves with Your Business

GAINS DEO doesn’t wait for your input; it guides you. GAINS uses embedded AI to optimize decisions across every tier of inventory, planning, and execution, refining and orchestrating actions in real-time. Powered by Agentic AI, GAINS continuously learns from your data to enhance outcomes, mitigate risk, and transform uncertainty into a competitive advantage.

- See trends before they cause disruption

- Simulate policy outcomes

- Understand trade-offs in plain language

- Collaborate across supply, finance, and operations

Every SKU Tells a Story

GAINS DEO helps you:

Align inventory decisions to your goals, not generic benchmarks

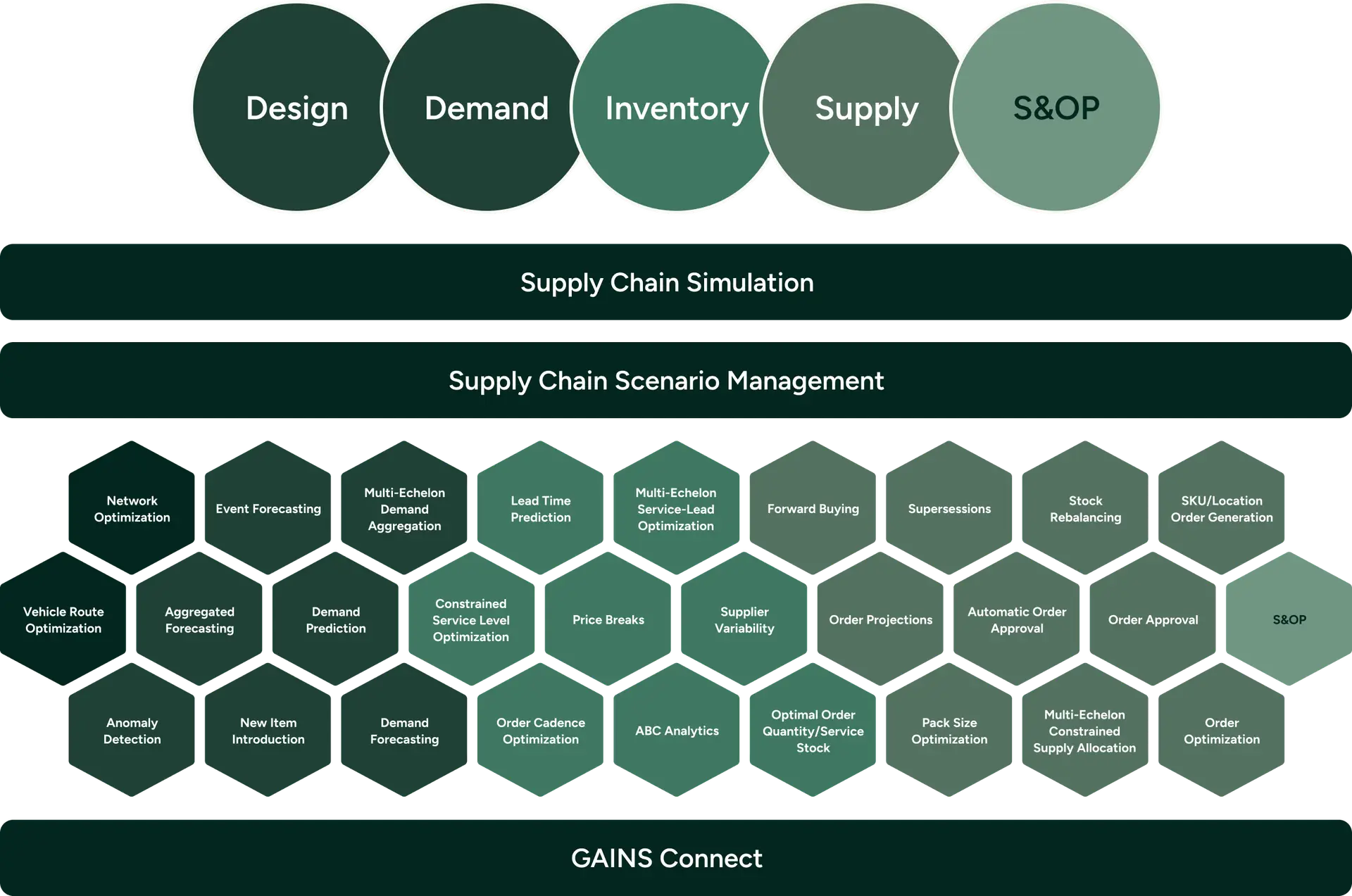

Core Features: what’s included

Inventory Policy Optimization

Model variability in demand, supply, and lead time to determine the right policy for every item.

Multi-Echelon Inventory Optimization (MEIO)

Right-size inventory across all levels of the distribution network—DCs, stores, plants, and suppliers—while minimizing working capital.

Service Level Optimization

Balance service and cost by setting item-specific targets that reflect your business goals—maximize profit, minimize cost, or meet specific turns.

Automated Stocking Strategies

Automatically determine when and where to stock—solving for interdependencies within BOMs, kits, or multi-tier networks.

Real Results, Real Customers

96%

increased customer service levels

$2.5M

increased profits in 12 months with 15% inventory reduction

“With better demand signals and the ability to evaluate multiple scenario tradeoffs on service and inventory performance, GAINS is a game-changer for the ACR team.”

Brett Barnello

Chief Supply Chain Officer

99%

target service achievement with 27% less inventory

$6.4M

annual savings with a 95% average increased case-fill rate post-implementation

Decisions We Power

Inventory Carrying Cost vs. Service Level

Trade-off

Higher service levels typically require more inventory— safety stock—which ties up working capital.

Decision

How much are you willing to spend to hit a 98% vs. a 95% service level?

Stockouts vs. Overstock

Trade-off

Buffer too little and face lost sales and frustrated customers. Buffer too much–– you inflate costs and risk obsolescence.

Decision

Which items (SKUs/customers) are worth the higher buffer, and which are not?

Centralized vs. Decentralized Stocking

Trade-off

Central stocking lowers costs and simplifies replenishment. Local– shortens lead times and improves responsiveness.

Decision

Where does speed matter most in your network, and where can you optimize for scale?

Forecast Accuracy vs. Responsiveness

Trade-off

Complex forecasts attempt precision, but real-world demand can still shift unexpectedly.

Decision

How much should you rely on predicted demand vs. demand sensing and responsive policies?

Service Level Targeting vs. Aggregate Efficiency

Trade-off

Optimizing service per SKU might not align with your overall network performance.

Decision

Would a 90% service level on low-margin SKUs hurt less than a 98% on bestsellers? What is the total network impact?

Minimum Order Quantities (MOQs) vs. Inventory Turns

Trade-off

Ordering in bulk may save on per-unit cost or satisfy vendor terms, but it increases holding costs.

Decision

Should you negotiate different vendor terms, or is holding extra stock justified by margin and risk?

Lead Time Risk vs. Safety Stock Investment

Trade-off

Long, unreliable lead times require more safety stock to preserve service, but raise capital costs.

Decision

Segment suppliers or invest in risk pooling and lead time prediction instead of more inventory?

Engineered for Clarity, Built for Flexibility, Designed for Resilience

GAINS Inventory Optimization is modular, adaptive, and resilient. Whether you’re managing thousands of SKUs or designing policies for complex networks, our platform helps you orchestrate decisions across time horizons and network tiers.

Launching something new?

No history? No problem. GAINS predicts demand for new items by matching product attributes to similar SKUs using fuzzy logic and machine learning.

Our MEIO engine doesn’t guess—it evolves.

GAINS applies genetic algorithms to fine-tune stocking strategies across every tier of your supply chain. From DCs to stores to suppliers, GAINS uses MEIO AI and ML to balance inventory where it matters most—network-wide.

Clarity at every level.

From the big picture to the individual SKU. Know exactly what’s driving cost, service, and inventory. No black boxes here! GAINS delivers granular, SKU-level insights so you can make precise decisions with confidence.

Why GAINS? Because We Think Differently

We believe the future belongs to those who design systems for change. GAINS is built on the belief that:

- There is no one right answer—only the right decision for now

- Systems must evolve as environments do

- Human expertise + intelligent automation = lasting impact

- Decision-making is the foundation of resilience

Let’s Architect Your Inventory Strategy

Talk with a GAINS specialist and explore how DEO can transform your inventory performance.

See GAINS in action—tailored to your specific network and product challenges.

A deeper dive into inventory policy strategies, service level optimization, and MEIO frameworks.

Learn more about DEO

Frequently asked questions

How does GAINS software help supply chain managers in reducing inventory carrying costs?

GAINS software provides powerful tools and insights that help supply chain managers reduce inventory carrying costs through a combination of advanced analytics, real-time data, and strategic optimization techniques. Here’s how:

- Demand Forecasting Accuracy: GAINS improves demand forecasting accuracy by leveraging advanced analytics and AI. This ensures that inventory levels align with actual demand, reducing excess stock and minimizing carrying costs.

- Dynamic Safety Stock Management: Our software dynamically adjusts safety stock levels to ensure you have the right amount of buffer stock to manage all of the sources of variability in your supply chain. This optimizes inventory buffers, preventing overstocking while ensuring sufficient supply to meet customer needs.

- Network-Wide Inventory Visibility: GAINS provides real-time visibility into inventory levels across the entire supply chain. This allows managers to make informed decisions about stock transfers, reordering, and demand fulfillment, reducing unnecessary inventory buildup.

- Optimized Replenishment Strategies: We implement optimized replenishment strategies that consider lead times, order quantities, and supplier reliability. This ensures timely restocking with minimal inventory holding, reducing carrying costs.

- Advanced Inventory Segmentation: GAINS software segments inventory based on various criteria, including demand patterns, product lifecycle, and profitability. This targeted approach helps prioritize high-value items and manage slow-moving stock more effectively.

- Continuous Monitoring and Alerts: Our software continuously monitors inventory levels and provides alerts and recommended actions for potential issues such as stockouts or excess. This proactive approach enables timely interventions to maintain optimal inventory levels.

- Scenario Analysis and Simulation: GAINS allows managers to perform scenario analysis and simulations to understand the impact of different inventory strategies. This helps identify the most cost-effective approaches to inventory management.

- Collaboration and Integration: Our software integrates seamlessly with other systems and promotes collaboration across departments. This ensures that inventory decisions are aligned with overall business objectives and operational constraints.

Can GAINS optimize inventory across a global supply chain with varying lead times and service requirements?

- Global Visibility: GAINS provides comprehensive visibility into inventory levels down to individual SKUs by location (SKUL) and movements across all locations in your supply chain. This real-time insight enables better coordination and informed decision-making to optimize inventory distribution.

- Advanced Analytics: Our advanced analytics tools account for the complexities of global supply chains, including varied lead times, transportation modes, and demand variations by region. This allows supply chain professionals to create precise and efficient inventory strategies.

- Lead Time Management: GAINS accurately models lead time variance across different suppliers and regions. Incorporating these lead times into our algorithms ensures that inventory levels stay balanced and aligned with service requirements.

- Service Level Optimization: We optimize inventory levels for all markets and products to meet your specific service requirements. This ensures high service levels and customer satisfaction while right-sizing inventory and carrying costs.

- Dynamic Replenishment: GAINS implements dynamic replenishment strategies that adapt to changes in demand and supply conditions. This flexibility ensures timely restocking and reduces the risk of stockouts or overstock situations.

- Scenario Planning and Simulation: Our software allows for scenario planning and simulations to evaluate the impact of various factors on your inventory performance. This helps to develop robust strategies to manage uncertainties and disruptions in the global supply chain.

- Integrated Supply Chain Solutions: GAINS Connect integrates seamlessly with other supply chain management systems, ensuring smooth data flow and collaboration across your supply operation. This holistic approach enhances overall supply chain efficiency.

- Continuous Improvement: We continuously monitor and analyze inventory performance, providing insights and recommendations for ongoing optimization. This commitment to continuous improvement ensures that your inventory strategies remain effective amid continual uncertainty.

Related Resources

Shipment delays, stockouts, forecast errors, production bottlenecks, and inventory mismatches — 90% of organizations encounter supply [...]

Organizations with high decision latency move slowly and risk losing their competitive edge in a [...]

With new brands emerging constantly, retailers are finding it harder than ever to stay competitive. [...]